Page 126 - Materials Chemistry, Second Edition

P. 126

110 3 Life Cycle Inventory Analysis

Polymer Polymer

production production

(PP-A) (PP-B)

Production A: Recycling Production B:

production and (Rec) production and

use use

(Pr-A) (Pr-B)

Load system A + B:

MSWI PP-A + Pr-A + Pr-B + MSWI

(MSWI-A) MVA-B + Rec (MSWI-B)

System A: Avoided burden: System B:

PP-A + Pr-A MVA-A + PP-B Pr-B + MSWI-B

Figure 3.20 Process pattern for coupled systems with system expansion 107) (disposal, here:

MSWI).

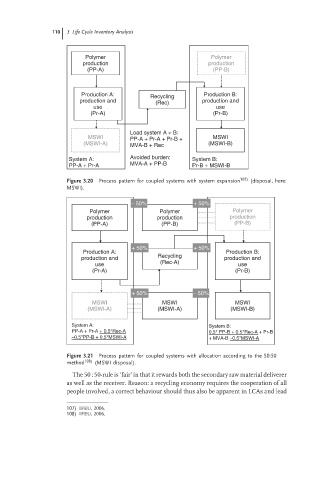

− 50% + 50%

Polymer Polymer Polymer

production production production

(PP-A) (PP-B) (PP-B)

+ 50% + 50%

Production A: Production B:

production and Recycling production and

use (Rec-A) use

(Pr-A) (Pr-B)

+ 50% − 50%

MSWI MSWI MSWI

(MSWI-A) (MSWI-A) (MSWI-B)

System A: System B:

PP-A + Pr-A + 0.5*Rec-A 0.5* PP-B + 0.5*Rec-A + Pr-B

−0.5*PP-B + 0.5*MSWI-A + MVA-B −0.5*MSWI-A

Figure 3.21 Process pattern for coupled systems with allocation according to the 50:50

method 108) (MSWI disposal).

The 50 : 50-rule is ‘fair’ in that it rewards both the secondary raw material deliverer

as well as the receiver. Reason: a recycling economy requires the cooperation of all

people involved, a correct behaviour should thus also be apparent in LCAs and lead

107) IFEU, 2006.

108) IFEU, 2006.