Page 123 - Materials Chemistry, Second Edition

P. 123

3.3 Allocation 107

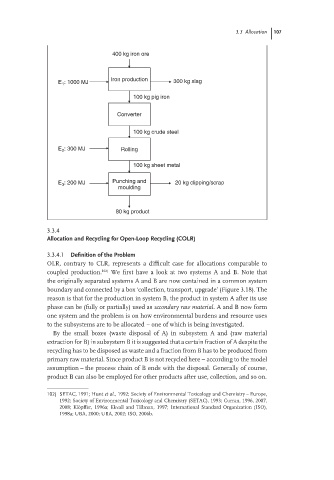

400 kg iron ore

Iron production

E : 1000 MJ 300 kg slag

1

100 kg pig iron

Converter

100 kg crude steel

: 300 MJ

E 2 Rolling

100 kg sheet metal

E 3 : 200 MJ Punching and 20 kg clipping/scrap

moulding

80 kg product

3.3.4

Allocation and Recycling for Open-Loop Recycling (COLR)

3.3.4.1 Definition of the Problem

OLR, contrary to CLR, represents a difficult case for allocations comparable to

coupled production. 102) We first have a look at two systems A and B. Note that

the originally separated systems A and B are now contained in a common system

boundary and connected by a box ‘collection, transport, upgrade’ (Figure 3.18). The

reason is that for the production in system B, the product in system A after its use

phase can be (fully or partially) used as secondary raw material. A and B now form

one system and the problem is on how environmental burdens and resource uses

to the subsystems are to be allocated – one of which is being investigated.

By the small boxes (waste disposal of A) in subsystem A and (raw material

extraction for B) in subsystem B it is suggested that a certain fraction of A despite the

recycling has to be disposed as waste and a fraction from B has to be produced from

primary raw material. Since product B is not recycled here – according to the model

assumption – the process chain of B ends with the disposal. Generally of course,

product B can also be employed for other products after use, collection, and so on.

102) SETAC, 1991; Hunt et al., 1992; Society of Environmental Toxicology and Chemistry – Europe,

1992; Society of Environmental Toxicology and Chemistry (SETAC), 1993; Curran, 1996, 2007,

2008; Kl¨ opffer, 1996a; Ekvall and Tillman, 1997; International Standard Organization (ISO),

1998a; UBA, 2000; UBA, 2002; ISO, 2006b.