Page 484 - Moving the Earth_ The Workbook of Excavation

P. 484

BLASTING AND TUNNELING

9.84 THE WORK

(LHD) bucket loading, and an automated guidance system for LHB machines. In other words, the

remote control is operated from a control room at a safe distance from the mining face. There the oper-

ator with joysticks maneuvers an LHD into the muck at the face of the mine to scoop up a bucket

full of muck, then moves the LHD to carry the muck to a dumping point. The bucket is filled by an

automated system based on hydraulic pressures, cylinder extensions, and load on the front axle.

With such automation the system ensures that the bucket will be essentially full every time.

This remote control system has proven to be successful at consistently filling the bucket of

each LHD at the face and displaying the load to the operator in the control room, improving pro-

ductivity, and reducing costs of the mining operation. The reduction of costs is made possible by

having a single operator handle several machines at a time. The system uses visual navigation and

each vehicle is equipped with a series of sensors, an on-board computer, and two cameras, one at

each end. The cameras transmit images through an optical tape that runs along the roof of the drift.

Extraction. Extraction is the operation of removing ore and other minerals that have already

been made accessible by development work.

ROOM-AND-PILLAR EXCAVATION

Minerals in extensive beds of fairly uniform thickness may be mined by a method known as “room

and pillar.” Coal, limestone, and salt are frequently dug in this way.

A number of parallel corridors (tunnels or drifts) are cut into the formation, and are connected by

series of parallel corridors crossing at right angles. There must be at least two of the main corridors

to provide for ventilation, and there may be as many as five in a set—two haulage, two ventilation,

and one spare. The corridors are the rooms, and the blocks or walls between them are the pillars.

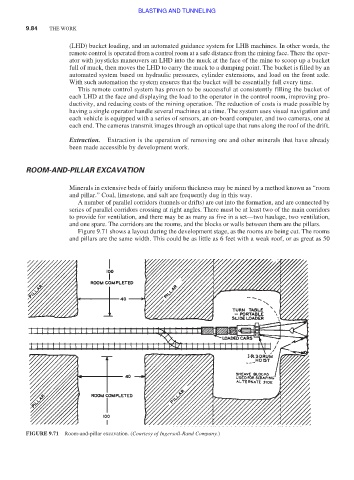

Figure 9.71 shows a layout during the development stage, as the rooms are being cut. The rooms

and pillars are the same width. This could be as little as 6 feet with a weak roof, or as great as 50

FIGURE 9.71 Room-and-pillar excavation. (Courtesy of Ingersoll-Rand Company.)