Page 485 - Moving the Earth_ The Workbook of Excavation

P. 485

BLASTING AND TUNNELING

BLASTING AND TUNNELING 9.85

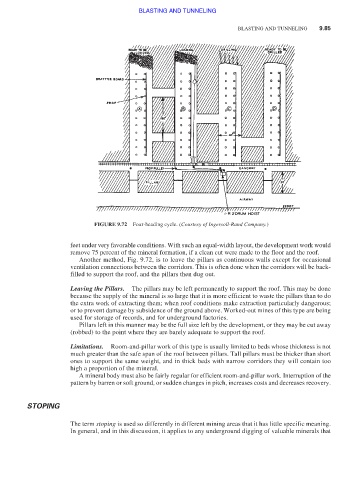

FIGURE 9.72 Four-heading cycle. (Courtesy of Ingersoll-Rand Company.)

feet under very favorable conditions. With such an equal-width layout, the development work would

remove 75 percent of the mineral formation, if a clean cut were made to the floor and the roof.

Another method, Fig. 9.72, is to leave the pillars as continuous walls except for occasional

ventilation connections between the corridors. This is often done when the corridors will be back-

filled to support the roof, and the pillars then dug out.

Leaving the Pillars. The pillars may be left permanently to support the roof. This may be done

because the supply of the mineral is so large that it is more efficient to waste the pillars than to do

the extra work of extracting them; when roof conditions make extraction particularly dangerous;

or to prevent damage by subsidence of the ground above. Worked-out mines of this type are being

used for storage of records, and for underground factories.

Pillars left in this manner may be the full size left by the development, or they may be cut away

(robbed) to the point where they are barely adequate to support the roof.

Limitations. Room-and-pillar work of this type is usually limited to beds whose thickness is not

much greater than the safe span of the roof between pillars. Tall pillars must be thicker than short

ones to support the same weight, and in thick beds with narrow corridors they will contain too

high a proportion of the mineral.

A mineral body must also be fairly regular for efficient room-and-pillar work. Interruption of the

pattern by barren or soft ground, or sudden changes in pitch, increases costs and decreases recovery.

STOPING

The term stoping is used so differently in different mining areas that it has little specific meaning.

In general, and in this discussion, it applies to any underground digging of valuable minerals that