Page 490 - Moving the Earth_ The Workbook of Excavation

P. 490

BLASTING AND TUNNELING

9.90 THE WORK

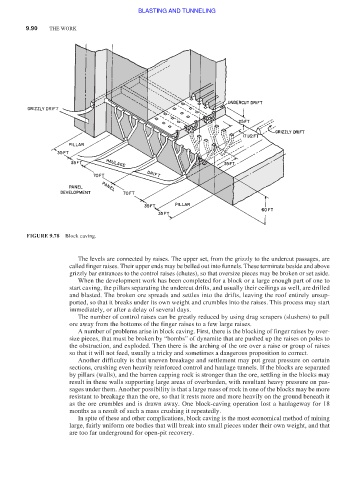

FIGURE 9.78 Block caving.

The levels are connected by raises. The upper set, from the grizzly to the undercut passages, are

called finger raises. Their upper ends may be belled out into funnels. These terminate beside and above

grizzly bar entrances to the control raises (chutes), so that oversize pieces may be broken or set aside.

When the development work has been completed for a block or a large enough part of one to

start caving, the pillars separating the undercut drifts, and usually their ceilings as well, are drilled

and blasted. The broken ore spreads and settles into the drifts, leaving the roof entirely unsup-

ported, so that it breaks under its own weight and crumbles into the raises. This process may start

immediately, or after a delay of several days.

The number of control raises can be greatly reduced by using drag scrapers (slushers) to pull

ore away from the bottoms of the finger raises to a few large raises.

A number of problems arise in block caving. First, there is the blocking of finger raises by over-

size pieces, that must be broken by “bombs” of dynamite that are pushed up the raises on poles to

the obstruction, and exploded. Then there is the arching of the ore over a raise or group of raises

so that it will not feed, usually a tricky and sometimes a dangerous proposition to correct.

Another difficulty is that uneven breakage and settlement may put great pressure on certain

sections, crushing even heavily reinforced control and haulage tunnels. If the blocks are separated

by pillars (walls), and the barren capping rock is stronger than the ore, settling in the blocks may

result in these walls supporting large areas of overburden, with resultant heavy pressure on pas-

sages under them. Another possibility is that a large mass of rock in one of the blocks may be more

resistant to breakage than the ore, so that it rests more and more heavily on the ground beneath it

as the ore crumbles and is drawn away. One block-caving operation lost a haulageway for 18

months as a result of such a mass crushing it repeatedly.

In spite of these and other complications, block caving is the most economical method of mining

large, fairly uniform ore bodies that will break into small pieces under their own weight, and that

are too far underground for open-pit recovery.