Page 489 - Moving the Earth_ The Workbook of Excavation

P. 489

BLASTING AND TUNNELING

BLASTING AND TUNNELING 9.89

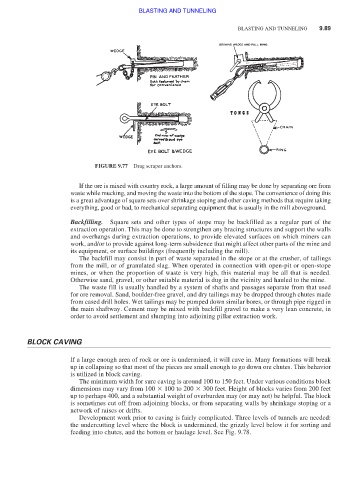

FIGURE 9.77 Drag scraper anchors.

If the ore is mixed with country rock, a large amount of filling may be done by separating ore from

waste while mucking, and moving the waste into the bottom of the stope. The convenience of doing this

is a great advantage of square sets over shrinkage stoping and other caving methods that require taking

everything, good or bad, to mechanical separating equipment that is usually in the mill aboveground.

Backfilling. Square sets and other types of stope may be backfilled as a regular part of the

extraction operation. This may be done to strengthen any bracing structures and support the walls

and overhangs during extraction operations, to provide elevated surfaces on which miners can

work, and/or to provide against long-term subsidence that might affect other parts of the mine and

its equipment, or surface buildings (frequently including the mill).

The backfill may consist in part of waste separated in the stope or at the crusher, of tailings

from the mill, or of granulated slag. When operated in connection with open-pit or open-stope

mines, or when the proportion of waste is very high, this material may be all that is needed.

Otherwise sand, gravel, or other suitable material is dug in the vicinity and hauled to the mine.

The waste fill is usually handled by a system of shafts and passages separate from that used

for ore removal. Sand, boulder-free gravel, and dry tailings may be dropped through chutes made

from cased drill holes. Wet tailings may be pumped down similar bores, or through pipe rigged in

the main shaftway. Cement may be mixed with backfill gravel to make a very lean concrete, in

order to avoid settlement and slumping into adjoining pillar extraction work.

BLOCK CAVING

If a large enough area of rock or ore is undermined, it will cave in. Many formations will break

up in collapsing so that most of the pieces are small enough to go down ore chutes. This behavior

is utilized in block caving.

The minimum width for sure caving is around 100 to 150 feet. Under various conditions block

dimensions may vary from 100 100 to 200 300 feet. Height of blocks varies from 200 feet

up to perhaps 400, and a substantial weight of overburden may (or may not) be helpful. The block

is sometimes cut off from adjoining blocks, or from separating walls by shrinkage stoping or a

network of raises or drifts.

Development work prior to caving is fairly complicated. Three levels of tunnels are needed:

the undercutting level where the block is undermined, the grizzly level below it for sorting and

feeding into chutes, and the bottom or haulage level. See Fig. 9.78.