Page 239 -

P. 239

SLOW SAND AND DIATOMACEOUS EARTH FILTRATION 9.15

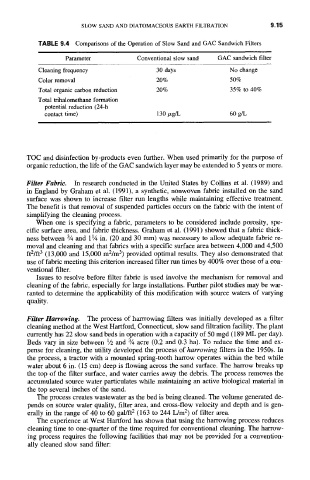

TABLE 9.4 Comparisons of the Operation of Slow Sand and GAC Sandwich Filters

Parameter Conventional slow sand GAC sandwich filter

Cleaning frequency 30 days No change

Color removal 20% 50%

Total organic carbon reduction 20% 35% to 40%

Total trihalomethane formation

potential reduction (24-h

contact time) 130/zg/L 60 g/L

TOC and disinfection by-products even further. When used primarily for the purpose of

organic reduction, the life of the GAC sandwich layer may be extended to 5 years or more.

Filter Fabric. In research conducted in the United States by Collins et al. (1989) and

in England by Graham et al. (1991), a synthetic, nonwoven fabric installed on the sand

surface was shown to increase filter run lengths while maintaining effective treatment.

The benefit is that removal of suspended particles occurs on the fabric with the intent of

simplifying the cleaning process.

When one is specifying a fabric, parameters to be considered include porosity, spe-

cific surface area, and fabric thickness. Graham et al. (1991) showed that a fabric thick-

ness between 3,4 and 11,4 in. (20 and 30 mm) was necessary to allow adequate fabric re-

moval and cleaning and that fabrics with a specific surface area between 4,000 and 4,500

ft2/ft 3 (13,000 and 15,000 m2/m 3) provided optimal results. They also demonstrated that

use of fabric meeting this criterion increased filter run times by 400% over those of a con-

ventional filter.

Issues to resolve before filter fabric is used involve the mechanism for removal and

cleaning of the fabric, especially for large installations. Further pilot studies may be war-

ranted to determine the applicability of this modification with source waters of varying

quality.

Filter Harrowing. The process of harrrowing filters was initially developed as a filter

cleaning method at the West Hartford, Connecticut, slow sand filtration facility. The plant

currently has 22 slow sand beds in operation with a capacity of 50 mgd (189 ML per day).

Beds vary in size between 1~ and 3,4 acre (0.2 and 0.3 ha). To reduce the time and ex-

pense for cleaning, the utility developed the process of harrowing filters in the 1950s. In

the process, a tractor with a mounted spring-tooth harrow operates within the bed while

water about 6 in. (15 cm) deep is flowing across the sand surface. The harrow breaks up

the top of the filter surface, and water carries away the debris. The process removes the

accumulated source water particulates while maintaining an active biological material in

the top several inches of the sand.

The process creates wastewater as the bed is being cleaned. The volume generated de-

pends on source water quality, filter area, and cross-flow velocity and depth and is gen-

erally in the range of 40 to 60 gal/ft 2 (163 to 244 L/m 2) of filter area.

The experience at West Hartford has shown that using the harrowing process reduces

cleaning time to one-quarter of the time required for conventional cleaning. The harrow-

ing process requires the following facilities that may not be provided for a convention-

ally cleaned slow sand filter: