Page 244 -

P. 244

9.20 CHAPTER NINE

Types of DE Filters. Two basic groups of DE filters are available. If source water is to

be forced through the filter under pressure, the containment vessel must be closed, as il-

lustrated in Figure 9.9. Filters operated under a vacuum, on the other hand, may be open

vessels.

Although there is theoretically no limitation to what pressure may be applied to a

pressure-type filter, practical considerations of pumping costs have limited head loss to a

maximum of 35 psi (241 kPa). Most systems used for drinking water filtration are de-

signed for a maximum head loss of 25 psi (172 kPa).

Filter Construction. Pressure filters are always constructed as cylindrical pressure ves-

sels mounted either vertically or horizontally. Most units fabricated today are made of

stainless steel for the shell and most internal parts. The type of stainless steel used de-

pends on the corrosivity of the water being treated.

Vacuum filters are built as rectangular tanks. Because of the low differential heads

they are subject to, vacuum filter containments and internal parts, except certain struc-

tural supports, are most often fabricated of plastics for their chemical resistance and

reduced maintenance. For larger units, the containment vessel may be constructed of

concrete.

Filter Elements. Inlet water flow is introduced to a DE filter through the containment

wall, fitted with an internal baffling device to prevent disturbance of the filter cake. Fil-

ter cake may be cleaned from the filter by scraping, vibration, hydraulic bumping (surg-

ing), or manually hosing down the septa from the top of an open vessel.

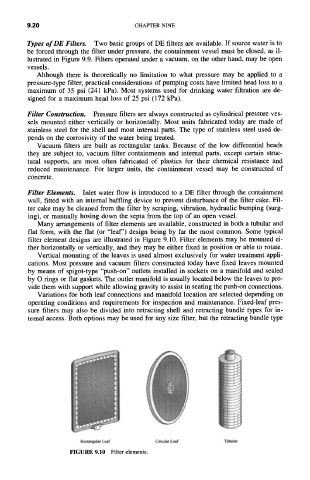

Many arrangements of filter elements are available, constructed in both a tubular and

flat form, with the flat (or "leaf') design being by far the most common. Some typical

filter element designs are illustrated in Figure 9.10. Filter elements may be mounted ei-

ther horizontally or vertically, and they may be either fixed in position or able to rotate.

Vertical mounting of the leaves is used almost exclusively for water treatment appli-

cations. Most pressure and vacuum filters constructed today have fixed leaves mounted

by means of spigot-type "push-on" outlets installed in sockets on a manifold and sealed

by O rings or flat gaskets. The outlet manifold is usually located below the leaves to pro-

vide them with support while allowing gravity to assist in seating the push-on connections.

Variations for both leaf connections and manifold location are selected depending on

operating conditions and requirements for inspection and maintenance. Fixed-leaf pres-

sure filters may also be divided into retracting shell and retracting bundle types for in-

ternal access. Both options may be used for any size filter, but the retracting bundle type

Rectangular Leaf Circular Leaf Tabular

FIGURE 9.10 Filter elements.