Page 245 -

P. 245

SLOW SAND AND DIATOMACEOUS EARTH FILTRATION 9.21

Fixed Leaf (Retracting Bundle) Fixed Leaf (Vacuum)

D

@

Fixed Leaf (Retracting Shell) Rotating Leaf

O Inlet O Sluicing Water Inlet (~ Retracting Shell/Bundle, Access Door O Leaves

(~ Outlet ~) Sluiced Slurry Outlet (~ Vent O Sluicing Header Drives, Shaft Drive

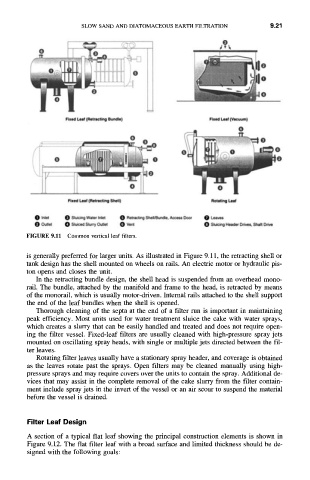

FIGURE 9.11 Common vertical leaf filters.

is generally preferred for larger units. As illustrated in Figure 9.11, the retracting shell or

tank design has the shell mounted on wheels on rails. An electric motor or hydraulic pis-

ton opens and closes the unit.

In the retracting bundle design, the shell head is suspended from an overhead mono-

rail. The bundle, attached by the manifold and frame to the head, is retracted by means

of the monorail, which is usually motor-driven. Internal rails attached to the shell support

the end of the leaf bundles when the shell is opened.

Thorough cleaning of the septa at the end of a filter run is important in maintaining

peak efficiency. Most units used for water treatment sluice the cake with water sprays,

which creates a slurry that can be easily handled and treated and does not require open-

ing the filter vessel. Fixed-leaf filters are usually cleaned with high-pressure spray jets

mounted on oscillating spray heads, with single or multiple jets directed between the fil-

ter leaves.

Rotating filter leaves usually have a stationary spray header, and coverage is obtained

as the leaves rotate past the sprays. Open filters may be cleaned manually using high-

pressure sprays and may require covers over the units to contain the spray. Additional de-

vices that may assist in the complete removal of the cake slurry from the filter contain-

ment include spray jets in the invert of the vessel or an air scour to suspend the material

before the vessel is drained.

Filter Leaf Design

A section of a typical flat leaf showing the principal construction elements is shown in

Figure 9.12. The flat filter leaf with a broad surface and limited thickness should be de-

signed with the following goals: