Page 247 -

P. 247

SLOW SAND AND DIATOMACEOUS EARTH FILTRATION 9.23

duces the extent of the recirculation required to deposit the material. The weave must also

be designed so that it sluices cleanly, drops the cake freely, and resists plugging and

damage.

One of the more common wire cloths for water filtration is a standard 24 × 110 Dutch

weave. Another type of weave is the multibraid, composed of bundles of wire in both di-

rections. This weave is less vulnerable to the entrapment of particles and blinding than

the standard weave. Woven wire cloth may also be "calendered," which involves passing

the cloth through compression rollers to flatten the rounded wire at the surface of the

weave. Calendering improves precoat retention characteristics and generally strengthens

the cloth against rough treatment.

Plastic cloth is used predominantly for vacuum-type DE filters and is available in a

variety of weaves using either polyester or polypropylene monofilament. Plastic cloth may

be supplied as a bag to envelop a filter leaf or as a cloth caulked into a leaf frame.

Binding Frame Closures. The binding frame surrounds the filter leaf to prevent leak-

age around the septum. The outside frame is also the principal structural element to pro-

vide rigidity and prevent warping. Depending on the shape, the outside binder may also

collect flow from the central chamber and supplement flow routing to the outlet nozzle.

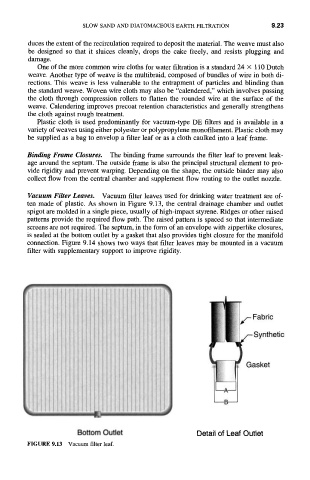

Vacuum Filter Leaves. Vacuum filter leaves used for drinking water treatment are of-

ten made of plastic. As shown in Figure 9.13, the central drainage chamber and outlet

spigot are molded in a single piece, usually of high-impact styrene. Ridges or other raised

patterns provide the required flow path. The raised pattern is spaced so that intermediate

screens are not required. The septum, in the form of an envelope with zipperlike closures,

is sealed at the bottom outlet by a gasket that also provides tight closure for the manifold

connection. Figure 9.14 shows two ways that filter leaves may be mounted in a vacuum

filter with supplementary support to improve rigidity.

iiii!i

i!~ii!

Bottom Outlet Detail of Leaf Outlet

FIGURE 9.13 Vacuum filter leaf.