Page 250 -

P. 250

9.26 CHAPTER NINE

The principal advantages of the pressure filter system are as follows:

• The ability to operate at application rates of up to 3 gpm/ft 2 (7.8 m/h) requires fewer

filter units to process a given amount of water.

• The enclosed filter units generally make a neater installation with minimum house-

keeping maintenance.

• A wide range of sizes of pressure units are available, from small up to about 3,000 ft 2

(280 m2).

The principal disadvantages of the pressure-type precoated filter system are the rela-

tively high initial cost of the filter units and somewhat higher power costs for operation

because of the higher operating pressure.

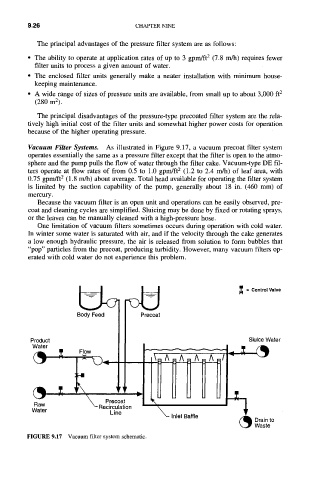

Vacuum Filter Systems. As illustrated in Figure 9.17, a vacuum precoat filter system

operates essentially the same as a pressure filter except that the filter is open to the atmo-

sphere and the pump pulls the flow of water through the filter cake. Vacuum-type DE fil-

ters operate at flow rates of from 0.5 to 1.0 gpm/ft 2 (1.2 to 2.4 m/h) of leaf area, with

0.75 gpm/ft 2 (1.8 m/h) about average. Total head available for operating the filter system

is limited by the suction capability of the pump, generally about 18 in. (460 ram) of

mercury.

Because the vacuum filter is an open unit and operations can be easily observed, pre-

coat and cleaning cycles are simplified. Sluicing may be done by fixed or rotating sprays,

or the leaves can be manually cleaned with a high-pressure hose.

One limitation of vacuum filters sometimes occurs during operation with cold water.

In winter some water is saturated with air, and if the velocity through the cake generates

a low enough hydraulic pressure, the air is released from solution to form bubbles that

"pop" particles from the precoat, producing turbidity. However, many vacuum filters op-

erated with cold water do not experience this problem.

= Control Valve

Body Feed Precoat

Sluice Water

Product

Water

-- ~. A A A A I

Raw ~. Precoat

Recirculation

Water Line ~- Inlet Baffle Drain to

Waste

FIGURE 9.17 Vacuum filter system schematic.