Page 246 -

P. 246

9.22 CHAPTER NINE

D rai nage

Collecl

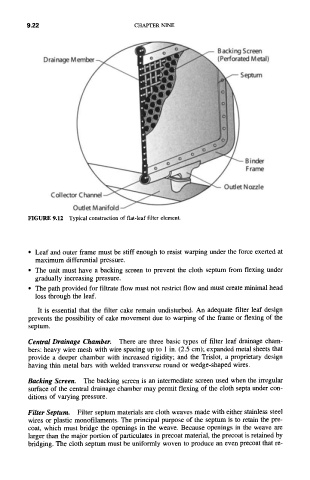

FIGURE 9.12 Typical construction of fiat-leaf filter element.

• Leaf and outer frame must be stiff enough to resist warping under the force exerted at

maximum differential pressure.

• The unit must have a backing screen to prevent the cloth septum from flexing under

gradually increasing pressure.

• The path provided for filtrate flow must not restrict flow and must create minimal head

loss through the leaf.

It is essential that the filter cake remain undisturbed. An adequate filter leaf design

prevents the possibility of cake movement due to warping of the frame or flexing of the

septum.

Central Drainage Chamber. There are three basic types of filter leaf drainage cham-

bers: heavy wire mesh with wire spacing up to 1 in. (2.5 cm); expanded metal sheets that

provide a deeper chamber with increased rigidity; and the Trislot, a proprietary design

having thin metal bars with welded transverse round or wedge-shaped wires.

Backing Screen. The backing screen is an intermediate screen used when the irregular

surface of the central drainage chamber may permit flexing of the cloth septa under con-

ditions of varying pressure.

Filter Septum. Filter septum materials are cloth weaves made with either stainless steel

wires or plastic monofilaments. The principal purpose of the septum is to retain the pre-

coat, which must bridge the openings in the weave. Because openings in the weave are

larger than the major portion of particulates in precoat material, the precoat is retained by

bridging. The cloth septum must be uniformly woven to produce an even precoat that re-