Page 252 -

P. 252

9.28 CHAPTER NINE

tank when DE concentration is determined before supplementary DE is added for use in

mixing a new batch of slurry.

For DE concentrations of 4% or less, case-hardened centrifugal pumps may be used

for slurry transfer. Abrasion-resistant chemical feed metering pumps are also acceptable

for these concentrations. Thicker slurries must be conveyed with either peristaltic-type

pumps or rubber-lined centrifugal pumps. To minimize breakdown of DE material, pipeline

velocities should be limited to no more than 8 ft/s (2.4 m/s), but must be maintained at

over 3 ft/s (0.9 m/s) to prevent settling.

Waste Disposal. Because it is predominantly inert, waste DE slurry may be easily treated

by thickening with polymers and dewatering on belt filters. DE slurry may also be set-

tled and concentrated in lagoons.

At large installations, DE may be recovered from wastes for reuse as body feed, but

it should never be used for precoat. Virgin DE should be used for precoat to provide a fi-

nal barrier for any pathogens that may pass through the upper levels of the cake. DE re-

covery saves costs of DE purchases and reduces the costs of waste disposal.

In the recovery process, separation of the lighter source water solids from the denser

DE is accomplished by pumping wastes through a series of vertical hydrocyclones. The

heavier DE material gravitates to the bottom discharge to exit into a collector tank, while

most of the source water solids and the finer fraction of the DE remain in the center core

of the unit. The finer material is then removed hydraulically from the top of each unit.

Because of the erosive nature of DE slurry, it is necessary to use hydrocyclones con-

structed of ceramic material and pumps designed for abrasion resistance.

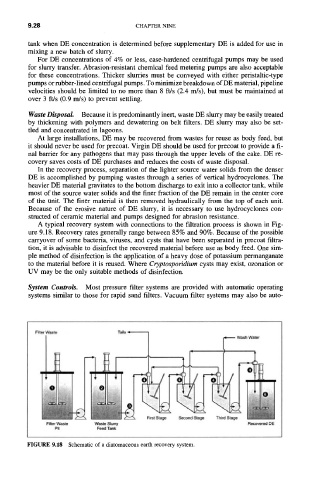

A typical recovery system with connections to the filtration process is shown in Fig-

ure 9. t 8. Recovery rates generally range between 85% and 90%. Because of the possible

carryover of some bacteria, viruses, and cysts that have been separated in precoat filtra-

tion, it is advisable to disinfect the recovered material before use as body feed. One sim-

ple method of disinfection is the application of a heavy dose of potassium permanganate

to the material before it is reused. Where Cryptosporidium cysts may exist, ozonation or

UV may be the only suitable methods of disinfection.

System Controls. Most pressure filter systems are provided with automatic operating

systems similar to those for rapid sand filters. Vacuum filter systems may also be auto-

Tails 9

Filter Waste

i Wash Water

i i

First Stage Second Stage Third Stage

Filter Waste Waste Slurry Recovered DE

Pit Feed Tank

FIGURE 9.18 Schematic of a diatomaceous earth recovery system.