Page 332 -

P. 332

11.12 CHAPTER ELEVEN

Approx. remaining alkalinity = 45 mg/L as CaCO3 (approx. minimum

solubility of Ca plus Mg as CaCo3)@

Approximate CO2 feed requirements remain the same as for Example 11.3.

Split-Treatment Excess Lime or Lime-Soda Ash Process

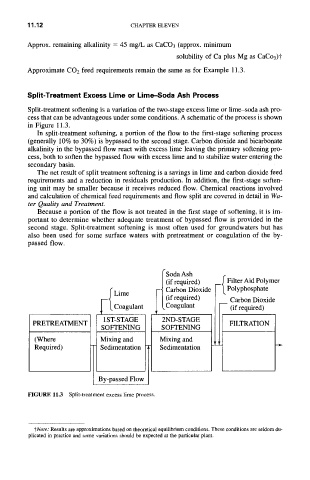

Split-treatment softening is a variation of the two-stage excess lime or lime-soda ash pro-

cess that can be advantageous under some conditions. A schematic of the process is shown

in Figure 11.3.

In split-treatment softening, a portion of the flow to the first-stage softening process

(generally 10% to 30%) is bypassed to the second stage. Carbon dioxide and bicarbonate

alkalinity in the bypassed flow react with excess lime leaving the primary softening pro-

cess, both to soften the bypassed flow with excess lime and to stabilize water entering the

secondary basin.

The net result of split treatment softening is a savings in lime and carbon dioxide feed

requirements and a reduction in residuals production. In addition, the first-stage soften-

ing unit may be smaller because it receives reduced flow. Chemical reactions involved

and calculation of chemical feed requirements and flow split are covered in detail in Wa-

ter Quality and Treatment.

Because a portion of the flow is not treated in the first stage of softening, it is im-

portant to determine whether adequate treatment of bypassed flow is provided in the

second stage. Split-treatment softening is most often used for groundwaters but has

also been used for some surface waters with pretreatment or coagulation of the by-

passed flow.

Soda Ash

f

_~" Filter Aid Polymer

|(if required)

L Polyphosphate

[-~Carbon Dioxide

_ ( Lime

[|(if required)

Carbon Dioxide

LCoagulant

L Coagulant

~ (if required)

1 ST-STAGE 2ND-STAGE

~

PRETREATMENT FILTRATION

SOFTENING SOFTENING

(Where Mixing and Mixing and

Required) Sedimentation Sedimentation

By-passed Flow

FIGURE 11.3 Split-treatment excess lime process.

tNote: Results are approximations based on theoretical equilibrium conditions. These conditions are seldom du-

plicated in practice and some variations should be expected at the particular plant.