Page 406 -

P. 406

13.3

MEMBRANE PROCESSES

I I I

Micron

0.001 0,01 0.1 1.0 10 100 1000

Scale

Approx I I I

MW

100 200 1000 10,000 20~0 100,000 500,000

r r p

Dissolved Organics Sand

Size

T•agel

of

' i

Selected

Viruses =Giardia t

I I

Water

I ' I

I f

Constituents

fSaltsl r Colloidsl I t C~pt~"~iridium

Media Filtration

j I i

[ ~ - -::'-:."::'] Microfiltration

Membrane

Ultrafiltratmn

Process*

Nanofiltration

• Media Filtration (Net a Membrane Process)

-~'.-':~iit Reverse Osmosis is Shown for Reference Only,

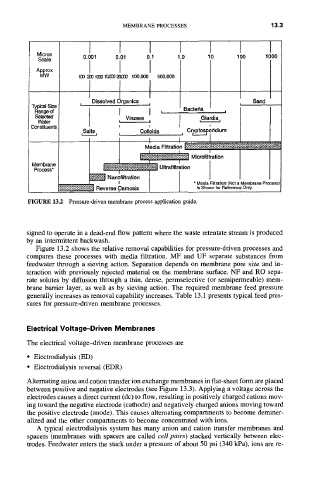

FIGURE 13.2 Pressure-driven membrane process application guide.

signed to operate in a dead-end flow pattern where the waste retentate stream is produced

by an intermittent backwash.

Figure 13.2 shows the relative removal capabilities for pressure-driven processes and

compares these processes with media filtration. MF and UF separate substances from

feedwater through a sieving action. Separation depends on membrane pore size and in-

teraction with previously rejected material on the membrane surface. NF and RO sepa-

rate solutes by diffusion through a thin, dense, permselective (or semipermeable) mem-

brane barrier layer, as well as by sieving action. The required membrane feed pressure

generally increases as removal capability increases. Table 13.1 presents typical feed pres-

sures for pressure-driven membrane processes.

Electrical Voltage-Driven Membranes

The electrical voltage-driven membrane processes are

• Electrodialysis (ED)

• Electrodialysis reversal (EDR)

Alternating anion and cation transfer ion exchange membranes in flat-sheet form are placed

between positive and negative electrodes (see Figure 13.3). Applying a voltage across the

electrodes causes a direct current (dc) to flow, resulting in positively charged cations mov-

ing toward the negative electrode (cathode) and negatively charged anions moving toward

the positive electrode (anode). This causes alternating compartments to become deminer-

alized and the other compartments to become concentrated with ions.

A typical electrodialysis system has many anion and cation transfer membranes and

spacers (membranes with spacers are called cell pairs) stacked vertically between elec-

trodes. Feedwater enters the stack under a pressure of about 50 psi (340 kPa), ions are re-