Page 411 -

P. 411

13.8 CHAPTER THIRTEEN

Hollow Fibers in

Epoxy Tube Sheet

Feed Port Concentrate Port

•

Pemleate Ports

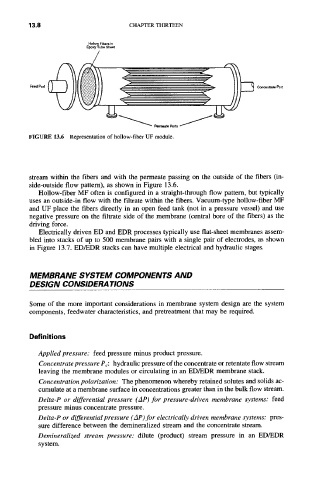

FIGURE 13.6 Representation of hollow-fiber UF module.

stream within the fibers and with the permeate passing on the outside of the fibers (in-

side-outside flow pattern), as shown in Figure 13.6.

Hollow-fiber MF often is configured in a straight-through flow pattern, but typically

uses an outside-in flow with the filtrate within the fibers. Vacuum-type hollow-fiber MF

and UF place the fibers directly in an open feed tank (not in a pressure vessel) and use

negative pressure on the filtrate side of the membrane (central bore of the fibers) as the

driving force.

Electrically driven ED and EDR processes typically use fiat-sheet membranes assem-

bled into stacks of up to 500 membrane pairs with a single pair of electrodes, as shown

in Figure 13.7. ED/EDR stacks can have multiple electrical and hydraulic stages.

MEMBRANE SYSTEM COMPONENTS AND

DESIGN CONSIDERATIONS

Some of the more important considerations in membrane system design are the system

components, feedwater characteristics, and pretreatment that may be required.

Definitions

Applied pressure: feed pressure minus product pressure.

Concentrate pressure Pc: hydraulic pressure of the concentrate or retentate flow stream

leaving the membrane modules or circulating in an ED/EDR membrane stack.

Concentration polarization: The phenomenon whereby retained solutes and solids ac-

cumulate at a membrane surface in concentrations greater than in the bulk flow stream.

Delta-P or differential pressure ( Ap) for pressure-driven membrane systems: feed

pressure minus concentrate pressure.

Delta-P or differential pressure (AP) for electrically driven membrane systems: pres-

sure difference between the demineralized stream and the concentrate stream.

Demineralized stream pressure: dilute (product) stream pressure in an ED/EDR

system.