Page 416 -

P. 416

MEMBRANE PROCESSES 13.13

lst-Pass RO 2nd-Pass RO

(High-Pressure Seawater (Low-Pressure Brackish

Membranes) i st-Pass Water Membranes)

Permeate

/ 2nd-Pass Concentrate

/' / t (Recycle)

Pretreated~~~

Seawater x ~ i ~ - -

~ i ~ " 2nd-Pass

Break ~ | Permeate

Tank v ....... .~

Concentrate Bypass

(to Energy Recovery Device) i

i

Clearwell

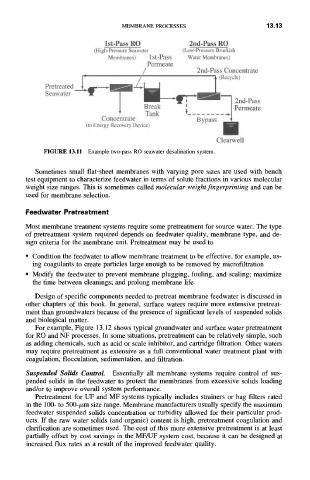

FIGURE 13.11 Example two-pass RO seawater desalination system.

Sometimes small flat-sheet membranes with varying pore sizes are used with bench

test equipment to characterize feedwater in terms of solute fractions in various molecular

weight size ranges. This is sometimes called molecular weight fingerprinting and can be

used for membrane selection.

Feedwater Pretreatment

Most membrane treatment systems require some pretreatment for source water. The type

of pretreatment system required depends on feedwater quality, membrane type, and de-

sign criteria for the membrane unit. Pretreatment may be used to

• Condition the feedwater to allow membrane treatment to be effective, for example, us-

ing coagulants to create particles large enough to be removed by microfiltration

• Modify the feedwater to prevent membrane plugging, fouling, and scaling; maximize

the time between cleanings; and prolong membrane life

Design of specific components needed to pretreat membrane feedwater is discussed in

other chapters of this book. In general, surface waters require more extensive pretreat-

ment than groundwaters because of the presence of significant levels of suspended solids

and biological matter.

For example, Figure 13.12 shows typical groundwater and surface water pretreatment

for RO and NF processes. In some situations, pretreatment can be relatively simple, such

as adding chemicals, such as acid or scale inhibitor, and cartridge filtration. Other waters

may require pretreatment as extensive as a full conventional water treatment plant with

coagulation, flocculation, sedimentation, and filtration.

Suspended Solids Control. Essentially all membrane systems require control of sus-

pended solids in the feedwater to protect the membranes from excessive solids loading

and/or to improve overall system performance.

Pretreatment for UF and MF systems typically includes strainers or bag filters rated

in the 100- to 500-/zm size range. Membrane manufacturers usually specify the maximum

feedwater suspended solids concentration or turbidity allowed for their particular prod-

ucts. If the raw water solids (and organic) content is high, pretreatment coagulation and

clarification are sometimes used. The cost of this more extensive pretreatment is at least

partially offset by cost savings in the MF/UF system cost, because it can be designed at

increased flux rates as a result of the improved feedwater quality.