Page 420 -

P. 420

MEMBRANE PROCESSES 13,17

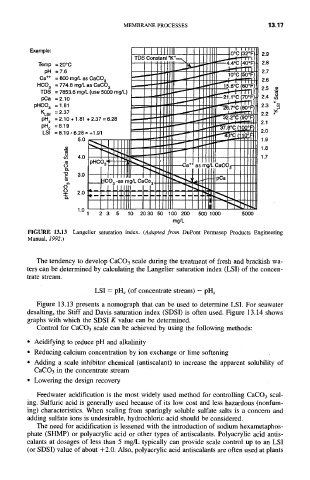

Example: Ooc (32OF

2.9

2.8

Temp =20°C ~ -- . ( F)

pH = 7.6 ~ 2.7

Ca +* = 800 mg/L as CaCO. ~ 10°C (50°1 =)

2.6

HCO 3 =774.8mg/LasCaCO 3 ~ 15.6oC(60oF""r-7~rr~

2.5 m

TDS = 7853.6 mg/L (use 50()0 nag/L) ~ ~ 1 1

-21.1°(:: (70°F) 2.4 ~

pCa = 2 10 ~

1"8 . I I ILIJ.tg,.---"l~ I IIIIIL .....b--+"t'~l/

pHCO, --2:3; ! ooF) 2.3 ~,

v

2.2 =

KLSIpH s = :).10 + 1.81 + 2.37 = 6.28 2.2°(:: (90*[=

2.1

pH c = 8.19 ~ I ~ o c ~ i

2.0

LSI = 8.19 - 6.28 = +1,91 3oc (110o

1.9

1.8

1.7

3.0 ~ nn~

I,__~CO 3 -as mg/L CaCo 3 P'~=

2.0

10

1 2 3 5 10 2030 50 100 200 500 1000 5000

mg/L

FIGURE 13.13 Langelier saturation index. (Adapted from DuPont Permasep Products Engineering

Manual, 1992.)

The tendency to develop CaCO3 scale during the treatment of fresh and brackish wa-

ters can be determined by calculating the Langelier saturation index (LSI) of the concen-

trate stream.

LSI = pHc (of concentrate stream) - pHs

Figure 13.13 presents a nomograph that can be used to determine LSI. For seawater

desalting, the Stiff and Davis saturation index (SDSI) is often used. Figure 13.14 shows

graphs with which the SDSI K value can be determined.

Control for CaCO3 scale can be achieved by using the following methods:

• Acidifying to reduce pH and alkalinity

• Reducing calcium concentration by ion exchange or lime softening

• Adding a scale inhibitor chemical (anfiscalant) to increase the apparent solubility of

CaCO3 in the concentrate stream

• Lowering the design recovery

Feedwater acidification is the most widely used method for controlling CaCO3 scal-

ing. Sulfuric acid is generally used because of its low cost and less hazardous (nonfum-

ing) characteristics. When scaling from sparingly soluble sulfate salts is a concern and

adding sulfate ions is undesirable, hydrochloric acid should be considered.

The need for acidification is lessened with the introduction of sodium hexametaphos-

phate (SHMP) or polyacrylic acid or other types of antiscalants. Polyacrylic acid antis-

calants at dosages of less than 5 mg/L typically can provide scale control up to an LSI

(or SDSI) value of about +2.0. Also, polyacrylic acid antiscalants are often used at plants