Page 423 -

P. 423

13.20 CHAPTER THIRTEEN

180

160

J

J

140

f

LJ

c~

o_

120

CO jf

t~

J

...J

100

E

80 J

E

.o_ 60

o~

40

20

0

0 5 10 15 20 25 30 35 40

Temperature, °C

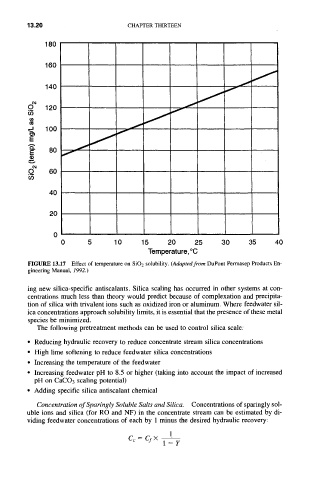

FIGURE 13.17 Effect of temperature on SiO2 solubility. (Adapted from DuPont Permasep Products En-

gineering Manual, 1992.)

ing new silica-specific antiscalants. Silica scaling has occurred in other systems at con-

centrations much less than theory would predict because of complexation and precipita-

tion of silica with trivalent ions such as oxidized iron or aluminum. Where feedwater sil-

ica concentrations approach solubility limits, it is essential that the presence of these metal

species be minimized.

The following pretreatment methods can be used to control silica scale:

• Reducing hydraulic recovery to reduce concentrate stream silica concentrations

• High lime softening to reduce feedwater silica concentrations

• Increasing the temperature of the feedwater

• Increasing feedwater pH to 8.5 or higher (taking into account the impact of increased

pH on CaCO3 scaling potential)

• Adding specific silica antiscalant chemical

Concentration of Sparingly Soluble Salts and Silica. Concentrations of sparingly sol-

uble ions and silica (for RO and NF) in the concentrate stream can be estimated by di-

viding feedwater concentrations of each by 1 minus the desired hydraulic recovery:

1

Cc=Cf× 1- Y