Page 168 - 15 Dangerously Mad Projects for the Evil Genius

P. 168

146 15 Dangerously Mad Projects for the Evil Genius

Step 3. Box the Project

As you can see from Figure 11-1 earlier, the PCB

is simply glued to the bottom of the plastic food

container using a hot glue gun. But before doing

that, we need to drill a small hole opposite the

push switch that turns the flash on. We will then be

able to poke a toothpick in it to turn the device on.

The glue will stick better if the plastic container

is roughened with sandpaper.

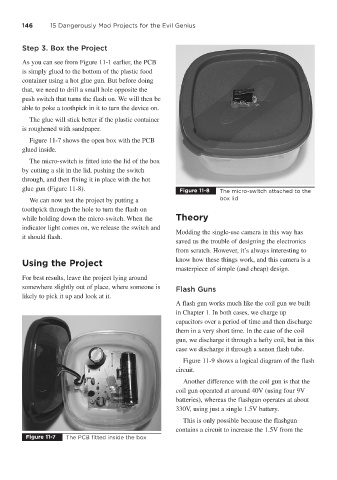

Figure 11-7 shows the open box with the PCB

glued inside.

The micro-switch is fitted into the lid of the box

by cutting a slit in the lid, pushing the switch

through, and then fixing it in place with the hot

glue gun (Figure 11-8). Figure 11-8 The micro-switch attached to the

We can now test the project by putting a box lid

toothpick through the hole to turn the flash on

while holding down the micro-switch. When the Theory

indicator light comes on, we release the switch and

Modding the single-use camera in this way has

it should flash.

saved us the trouble of designing the electronics

from scratch. However, it’s always interesting to

Using the Project know how these things work, and this camera is a

masterpiece of simple (and cheap) design.

For best results, leave the project lying around

somewhere slightly out of place, where someone is

Flash Guns

likely to pick it up and look at it.

A flash gun works much like the coil gun we built

in Chapter 1. In both cases, we charge up

capacitors over a period of time and then discharge

them in a very short time. In the case of the coil

gun, we discharge it through a hefty coil, but in this

case we discharge it through a xenon flash tube.

Figure 11-9 shows a logical diagram of the flash

circuit.

Another difference with the coil gun is that the

coil gun operated at around 40V (using four 9V

batteries), whereas the flashgun operates at about

330V, using just a single 1.5V battery.

This is only possible because the flashgun

contains a circuit to increase the 1.5V from the

Figure 11-7 The PCB fitted inside the box