Page 227 - 3D Fibre Reinforced Polymer Composites

P. 227

216 30 Fibre Reinforced Polymer Composites

example, Freitas et al. (1994) found that the compression-after-impact strength of a

carbodepoxy composite was nearly 50% higher when reinforced with Z-fibersTM.

9.5 Z-PINNED JOINTS

As mentioned earlier, a potential application of Z-fiberm technology is for the

reinforcement of composite structures such as lap and blade-stiffened composite joints.

While the mechanical performance of z-pinned joints is still being evaluated,

preliminary studies reveal that these joints have much better load-bearing properties

than joints made using conventional joining techniques such as adhesive bonding or co-

curing. For example, Rugg et al. (1998) found that Z-fibersTM are highly effective in

improving the mechanical properties of composite lap joints, with z-pinning producing

a large increase in the shear modulus and about a 100% rise in the failure load.

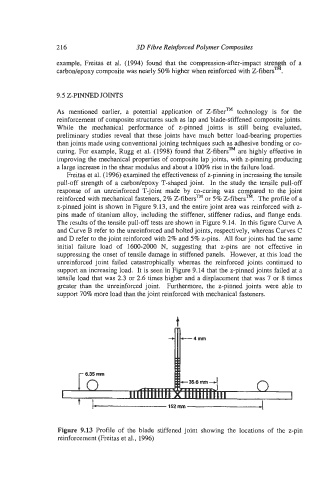

Freitas et al. (1996) examined the effectiveness of z-pinning in increasing the tensile

pull-off strength of a carbodepoxy T-shaped joint. In the study the tensile pull-off

response of an unreinforced T-joint made by co-curing was compared to the joint

reinforced with mechanical fasteners, 2% Z-fibers-rM or 5% Z-fibersTM. The profile of a

z-pinned joint is shown in Figure 9.13, and the entire joint area was reinforced with z-

pins made of titanium alloy, including the stiffener, stiffener radius, and flange ends.

The results of the tensile pull-off tests are shown in Figure 9.14. In this figure Curve A

and Curve B refer to the unreinforced and bolted joints, respectively, whereas Curves C

and D refer to the joint reinforced with 2% and 5% z-pins. All four joints had the same

initial failure load of 1600-2000 N, suggesting that z-pins are not effective in

suppressing the onset of tensile damage in stiffened panels. However, at this load the

unreinforced joint failed catastrophically whereas the reinforced joints continued to

support an increasing load. It is seen in Figure 9.14 that the z-pinned joints failed at a

tensile load that was 2.3 or 2.6 times higher and a displacement that was 7 or 8 times

greater than the unreinforced joint. Furthermore, the z-pinned joints were able to

support 70% more load than the joint reinforced with mechanical fasteners.

t

Figure 9.13 Profile of the blade stiffened joint showing the locations of the z-pin

reinforcement (Freitas et al., 1996)