Page 248 - 3D Fibre Reinforced Polymer Composites

P. 248

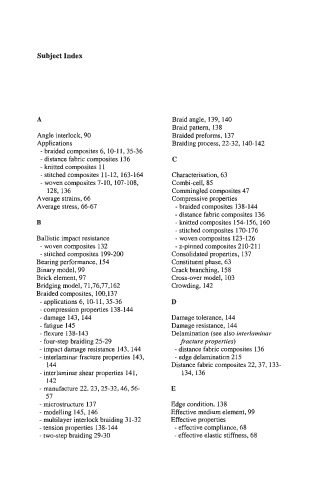

Subject Index

A Braid angle, 139, 140

Braid pattern, 138

Angle interlock, 90 Braided preforms, 137

Applications Braiding process, 22-32, 140-142

- braided composites 6, 10-1 1,35-36

- distance fabric composites 136 C

- knitted composites 11

- stitched composites 11-12, 163-164 Characterisation, 63

- woven composites 7-10, 107-108, Combi-cell, 85

128,136 Commingled composites 47

Average strains, 66 Compressive properties

Average stress, 66-67 - braided composites 138-144

- distance fabric composites 136

B - knitted composites 154-156, 160

- stitched composites 170-176

Ballistic impact resistance - woven composites 123-126

- woven composites 132 - z-pinned composites 2 10-2 1 1

- stitched composites 199-200 Consolidated properties, 137

Bearing performance, 154 Constituent phase, 63

Binary model, 99 Crack branching, 158

Brick element, 97 Cross-over model, 103

Bridging model, 7 1,76,77,162 Crowding, 142

Braided composites, 100,137

- applications 6, 10-1 1,35-36 D

- compression properties 138- 144

- damage 143,144 Damage tolerance, 144

- fatigue 145 Damage resistance, 144

- flexure 138-143 Delamination (see also interlaminar

- four-step braiding 25-29 fracture properties)

- impact damage resistance 143,144 - distance fabric composites 136

- interlaminar fracture properties 143, - edge delamination 2 15

144 Distance fabric composites 22,37, 133-

- interlaminar shear properties 14 1, 134,136

142

- manufacture 22,23,25-32,46,56- E

57

- microstructure 137 Edge condition, 138

- modelling 145, 146 Effective medium element, 99

- multilayer interlock braiding 3 1-32 Effective properties

- tension properties 138- 144 - effective compliance, 68

- two-step braiding 29-30 - effective elastic stiffness, 68