Page 28 - 3D Fibre Reinforced Polymer Composites

P. 28

Manufacture of 30 Fibre Preforms 17

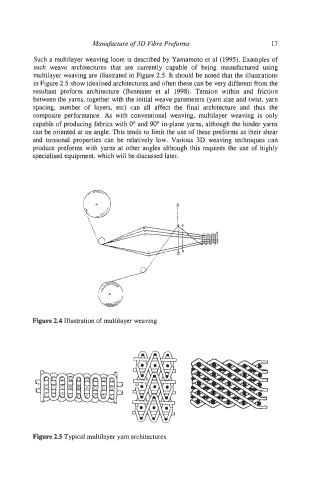

Such a multilayer weaving loom is described by Yamamoto et a1 (1995). Examples of

such weave architectures that are currently capable of being manufactured using

multilayer weaving are illustrated in Figure 2.5. It should be noted that the illustrations

in Figure 2.5 show idealised architectures and often these can be very different from the

resultant preform architecture (Bannister et a1 1998). Tension within and friction

between the yarns, together with the initial weave parameters (yam size and twist, yarn

spacing, number of layers, etc) can all affect the final architecture and thus the

composite performance. As with conventional weaving, multilayer weaving is only

capable of producing fabrics with 0" and 90" in-plane yams, although the binder yarns

can be oriented at an angle. This tends to limit the use of these preforms as their shear

and torsional properties can be relatively low. Various 3D weaving techniques can

produce preforms with yarns at other angles although this requires the use of highly

specialised equipment, which will be discussed later.

Figure 2.4 Illustration of multilayer weaving

Figure 2.5 Typical multilayer yarn architectures