Page 25 - 3D Fibre Reinforced Polymer Composites

P. 25

14 30 Fibre Reinforced Polymer Composites

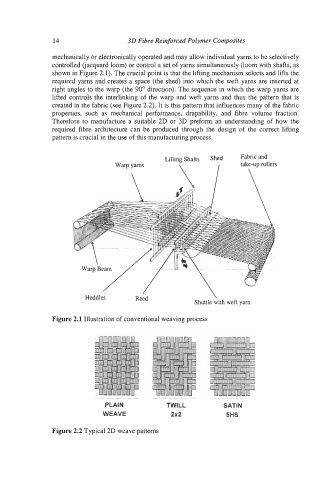

mechanically or electronically operated and may allow individual yarns to be selectively

controlled (jacquard loom) or control a set of yarns simultaneously (loom with shafts, as

shown in Figure 2.1). The crucial point is that the lifting mechanism selects and lifts the

required yarns and creates a space (the shed) into which the weft yarns are inserted at

right angles to the warp (the 90" direction). The sequence in which the warp yarns are

lifted controls the interlinking of the warp and weft yarns and thus the pattern that is

created in the fabric (see Figure 2.2). It is this pattern that influences many of the fabric

properties, such as mechanical performance, drapability, and fibre volume fraction.

Therefore to manufacture a suitable 2D or 3D preform an understanding of how the

required fibre architecture can be produced through the design of the correct lifting

pattern is crucial in the use of this manufacturing process.

/ / \

Heddles Reed \

Shuttle with weft yam

Figure 2.1 Illustration of conventional weaving process

PLAIN TWILL SATIN

WEAVE 2x2 5HS

Figure 2.2 Typical 2D weave patterns