Page 21 - 3D Fibre Reinforced Polymer Composites

P. 21

10 3D Fibre Reinforced Polymer Composites

to Mach 8 (-2600 ds) (Kandero, 2001). The 3D material is a ceramic-based composite

consisting of 3D woven carbon fibres in a silicon carbide matrix. The 3D composite is

used in the combustion chamber to the Scramjet engine. A key benefit of using 3D

woven composite is the ability to manufacture the chamber as a single piece by 3D

weaving, and this reduces connection issues and leakage problems associated with

conventional fabrication methods.

Apart from these aerospace applications, the only other uses of 3D woven composite

is the very occasional use in the repair of damaged boat hulls, I-beams in the roof of a

ski chair-lift building in Germany (Mtiller et al., 1994), manhole covers, sporting goods

such as shin guards and helmets, and ballistic protection for police and military

personnel (Mouritz et al., 1999). 3D woven composite is not currently used as a

biomedical material, although its potential use in leg prosthesis has been explored

(Limmer et al., 1996).

1.2.2 Applications of 3D Braided Composites

The braiding process is familiar to many fields of engineering as standard 2D braided

carbon and glass fabric have been used for many years in a variety of high technology

items, such as golf clubs, aircraft propellers and yacht masts (Popper, 1991). 3D

braided preform has a number of important advantages over many types of 2D fabric

preforms and prepreg tapes, including high levels of conformability, drapability,

torsional stability and structural integrity. Furthermore, 3D braiding processes are

capable of forming intricately-shaped preforms and the process can be varied during

operation to produce changes in the cross-sectional shape as well as to produce tapers,

holes, bends and bifurcations in the final preform.

Potential aerospace applications for 3D braided composites are listed in Table 1.2,

and include airframe spars, F-section fuselage frames, fuselage barrels, tail shafts, rib

stiffened panels, rocket nose cones, and rocket engine nozzles (Dexter, 1996; Brown,

1991; Mouritz et al., 1999). A variety of other components have been made of 3D

braided composite as demonstration items, including I-beams (Yau et al., 1986; Brown,

1991; Chiu et al., 1994; Fukuta, 1995; Wulfhorst et al., 1995), bifurcated beams (Popper

and McConnell, 1987), connecting rods (Yau et al., 1986), and C-, J- and T-section

panels (KO, 1984; Crane and Camponesch, 1986; Macander et al., 1986; Gause and

AIper, 1987; Popper and McConnell, 1987; Malkan and KO, 1989; Brookstein, 1990;

Brookstein, 1991; Fedro and Willden, 1991; Gong and Sankar, 1991; Brookstein, 1993;

Dexter, 1996).

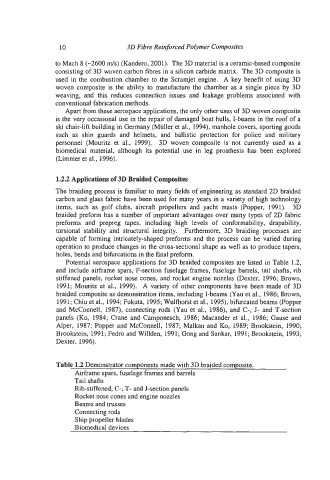

Table 1.2 Demonstrator components made with 3D braided composite.

Airframe spars, fuselage frames and barrels

Tail shafts

Rib-stiffened, C-, T- and J-section panels

Rocket nose cones and engine nozzles

Beams and trusses

Connecting rods

Ship propeller blades

Biomedical devices