Page 20 - 3D Fibre Reinforced Polymer Composites

P. 20

Introduction 9

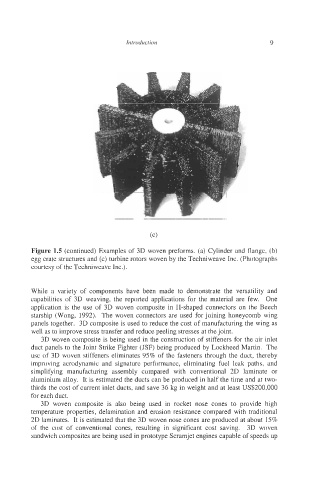

Figure 1.5 (continued) Examples of 3D woven preforms. (a) Cylinder and flange, (b)

egg crate structures and (c) turbine rotors woven by the Techniweave Inc. (Photographs

courtesy of the Techniweave Inc.).

While a variety of components have been made to demonstrate the versatility and

capabilities of 3D weaving, the reported applications for the material are few. One

application is the use of 3D woven composite in H-shaped connectors on the Beech

starship (Wong, 1992). The woven connectors are used for joining honeycomb wing

panels together. 3D composite is used to reduce the cost of manufacturing the wing as

well as to improve stress transfer and reduce peeling stresses at the joint.

3D woven composite is being used in the construction of stiffeners for the air inlet

duct panels to the Joint Strike Fighter (JSF) being produced by Lockheed Martin. The

use of 3D woven stiffeners eliminates 95% of the fasteners through the duct, thereby

improving aerodynamic and signature performance, eliminating fuel leak paths, and

simplifying manufacturing assembly compared with conventional 2D laminate or

aluminium alloy. It is estimated the ducts can be produced in half the time and at two-

thirds the cost of current inlet ducts, and save 36 kg in weight and at least US$200,000

for each duct.

3D woven composite is also being used in rocket nose cones to provide high

temperature properties, delamination and erosion resistance compared with traditional

2D laminates. It is estimated that the 3D woven nose cones are produced at about 15%

of the cost of conventional cones, resulting in significant cost saving. 3D woven

sandwich composites are being used in prototype Scramjet engines capable of speeds up