Page 18 - 3D Fibre Reinforced Polymer Composites

P. 18

Introduction 7

It is worth noting that these early 3D composites were made of carbon-carbon materials

and not fibre reinforced polymers. The need for 3D FRP composites was not fully

appreciated in the 1960s, and it was not until the mid-1980s that development

commenced on these materials. From 1985 to 1997 a NASA-lead study known as the

‘Advanced Composite Technology Program’ (ACTP), that included participants from

aircraft companies, composite suppliers and the textiles industry, was instrumental in

the research and development of 3D FRP composites (Dow and Dexter, 1997). The

program examined the potential of the textile processes of weaving, braiding, knitting

and stitching to produce advanced 3D composites for aircraft components.

Developmental work from the ACTP, combined with studies performed by other

research institutions, has produced an impressive variety of components and structures

made using 3D composites, and some of these are described below. However, due to

the commercial sensitivity of some components only those reported in the open

literature will be described.

1.2.1 Applications of 3D Woven Composites

Weaving is a process that has been used for over 50 years to produce single-layer,

broad-cloth fabric for use as fibre reinforcement to composites. It is only relatively

recently, however, that weaving techniques have been modified to produce 3D woven

materials that contain through-thickness fibres binding together the in-plane fabrics. A

variety of 3D woven composites have been manufactured using modified weaving

looms with different amounts of x-, y- and z-direction fibres so that the properties can

be tailored to a specific application. The great flexibility of the 3D weaving process

means that a wide variety of composite components have been developed for aerospace,

marine, civil infrastructure and medical applications (Mouritz et al., 1999). However,

only a few 3D woven components are currently used; most of the components have

been manufactured as demonstration items to showcase the potential applications of 3D

woven composites. A list of applications for 3D woven composites is given in Table

1.1 and some woven preform structures are shown in Figure 1.5. It is seen that a range

of intricate shapes can be integrally woven for possible applications as flanges, turbine

rotors, beams and cylinders. In the production of these demonstration items it has been

proven in many cases that it is faster and cheaper to manufacture 3D woven components

than 2D laminates, particularly for complex shapes. Furthermore, 3D woven

components have superior delamination resistance and impact damage tolerance.

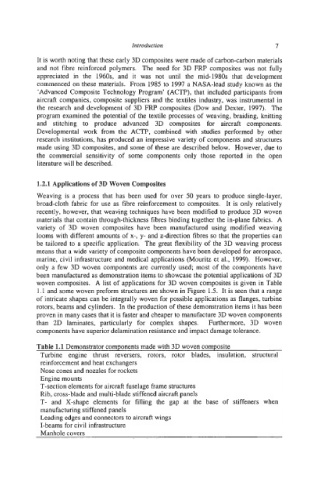

Table 1.1 Demonstrator components made with 3D woven composite

Turbine engine thrust reversers, rotors, rotor blades, insulation, structural

reinforcement and heat exchangers

Nose cones and nozzles for rockets

Engine mounts

T-section elements for aircraft fuselage frame structures

Rib, cross-blade and multi-blade stiffened aircraft panels

T- and X-shape elements for filling the gap at the base of stiffeners when

manufacturing stiffened panels

Leading edges and connectors to aircraft wings

I-beams for civil infrastructure

Manhole covers