Page 13 - 3D Fibre Reinforced Polymer Composites

P. 13

2 30 Fibre Reinforced Polymer Composites

glass fabric that must be stacked and consolidated by hand. The lack of a z-direction

binder means the plies must be individually stacked and that adds considerably to the

fabrication time. Furthermore, the lack of through-thickness fibres means that the plies

can slip during lay-up, and this can misalign the fibre orientations in the composite

component. These problems can be alleviated to some extent by semi-automated

processes that reduce the amount of labour, although the equipment is very expensive

and is often only suitable for fabricating certain types of structures, such as flat and

slightly curved panels. A further problem with fabricating composites is that production

rates are often low because of the slow curing of the resin matrix, even at elevated

temperature.

Y

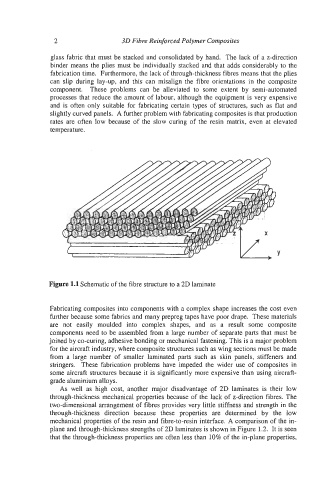

Figure 1.1 Schematic of the fibre structure to a 2D laminate

Fabricating composites into components with a complex shape increases the cost even

further because some fabrics and many prepreg tapes have poor drape. These materials

are not easily moulded into complex shapes, and as a result some composite

components need to be assembled from a large number of separate parts that must be

joined by co-curing, adhesive bonding or mechanical fastening. This is a major problem

for the aircraft industry, where composite structures such as wing sections must be made

from a large number of smaller laminated parts such as skin panels, stiffeners and

stringers. These fabrication problems have impeded the wider use of composites in

some aircraft structures because it is significantly more expensive than using aircraft-

grade aluminium alloys.

As well as high cost, another major disadvantage of 2D laminates is their low

through-thickness mechanical properties because of the lack of z-direction fibres. The

two-dimensional arrangement of fibres provides very little stiffness and strength in the

through-thickness direction because these properties are determined by the low

mechanical properties of the resin and fibre-to-resin interface. A comparison of the in-

plane and through-thickness strengths of 2D laminates is shown in Figure 1.2. It is seen

that the through-thickness properties are often less than 10% of the in-plane properties,