Page 17 - 3D Fibre Reinforced Polymer Composites

P. 17

6 30 Fibre Reinforced Polymer Composites

1.2 INTRODUCTION TO 3D FRF' COMPOSITES

Since the late-l960s, various types of composite materials with three-dimensional (3D)

fibre structures (incorporating z-direction fibres) have been developed to overcome the

shortcomings of 2D laminates. That is, the development of 3D composites has been

driven by the needs to reduce fabrication cost, increase through-thickness mechanical

properties and improve impact damage tolerance. The development of 3D composites

has been undertaken largely by the aerospace industry due to increasing demands on

FRP materials in load-bearing structures to aircraft, helicopters and space-craft. The

marine, construction and automotive industries have supported the developments. 3D

composites are made using the textile processing techniques of weaving, knitting,

braiding and stitching. 3D composites are also made using a novel process known as z-

pinning.

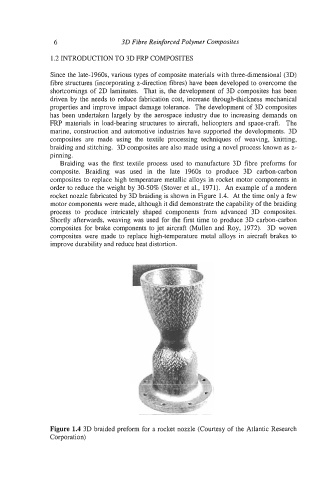

Braiding was the first textile process used to manufacture 3D fibre preforms for

composite. Braiding was used in the late 1960s to produce 3D carbon-carbon

composites to replace high temperature metallic alloys in rocket motor components in

order to reduce the weight by 30-5096 (Stover et al., 1971). An example of a modern

rocket nozzle fabricated by 3D braiding is shown in Figure 1.4. At the time only a few

motor components were made, although it did demonstrate the capability of the braiding

process to produce intricately shaped components from advanced 3D composites.

Shortly afterwards, weaving was used for the first time to produce 3D carbon-carbon

composites for brake components to jet aircraft (Mullen and Roy, 1972). 3D woven

composites were made to replace high-temperature metal alloys in aircraft brakes to

improve durability and reduce heat distortion.

Figure 1.4 3D braided preform for a rocket nozzle (Courtesy of the Atlantic Research

Corporation)