Page 54 - 3D Fibre Reinforced Polymer Composites

P. 54

Manufacture of 30 Fibre Preforms 43

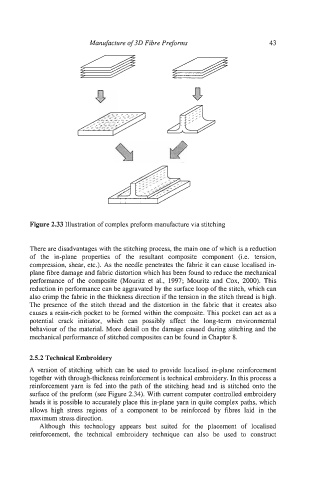

Figure 2.33 Illustration of complex preform manufacture via stitching

There are disadvantages with the stitching process, the main one of which is a reduction

of the in-plane properties of the resultant composite component (i.e. tension,

compression, shear, etc.). As the needle penetrates the fabric it can cause localised in-

plane fibre damage and fabric distortion which has been found to reduce the mechanical

performance of the composite (Mouritz et al., 1997; Mouritz and Cox, 2000). This

reduction in performance can be aggravated by the surface loop of the stitch, which can

also crimp the fabric in the thickness direction if the tension in the stitch thread is high.

The presence of the stitch thread and the distortion in the fabric that it creates also

causes a resin-rich pocket to be formed within the composite. This pocket can act as a

potential crack initiator, which can possibly affect the long-term environmental

behaviour of the material. More detail on the damage caused during stitching and the

mechanical performance of stitched composites can be found in Chapter 8.

2.5.2 Technical Embroidery

A version of stitching which can be used to provide localised in-plane reinforcement

together with through-thickness reinforcement is technical embroidery. In this process a

reinforcement yarn is fed into the path of the stitching head and is stitched onto the

surface of the preform (see Figure 2.34). With current computer controlled embroidery

heads it is possible to accurately place this in-plane yarn in quite complex paths, which

allows high stress regions of a component to be reinforced by fibres laid in the

maximum stress direction.

Although this technology appears best suited for the placement of localised

reinforcement, the technical embroidery technique can also be used to construct