Page 56 - 3D Fibre Reinforced Polymer Composites

P. 56

Manufacture of 30 Fibre Preforms 45

2.5.3 %Pinning

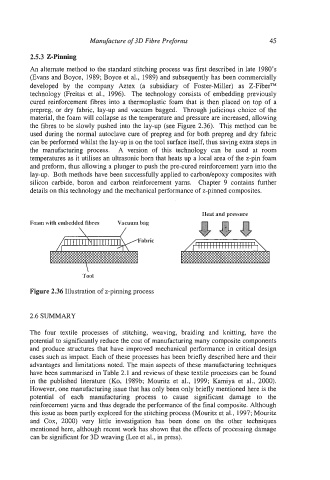

An alternate method to the standard stitching process was first described in late 1980's

(Evans and Boyce, 1989; Boyce et al., 1989) and subsequently has been commercially

developed by the company Aztex (a subsidiary of Foster-Miller) as Z-FiberTM

technology (Freitas et al., 1996). The technology consists of embedding previously

cured reinforcement fibres into a thermoplastic foam that is then placed on top of a

prepreg, or dry fabric, lay-up and vacuum bagged. Through judicious choice of the

material, the foam will collapse as the temperature and pressure are increased, allowing

the fibres to be slowly pushed into the lay-up (see Figure 2.36). This method can be

used during the normal autoclave cure of prepreg and for both prepreg and dry fabric

can be performed whilst the lay-up is on the tool surface itself, thus saving extra steps in

the manufacturing process. A version of this technology can be used at room

temperatures as it utilises an ultrasonic horn that heats up a local area of the z-pin foam

and preform, thus allowing a plunger to push the pre-cured reinforcement yarn into the

lay-up. Both methods have been successfully applied to carbodepoxy composites with

silicon carbide, boron and carbon reinforcement yarns. Chapter 9 contains further

details on this technology and the mechanical performance of z-pinned composites.

Heat and pressure

Foam with embedded fibres Vacuum bag

Tool

Figure 2.36 Illustration of z-pinning process

2.6 SUMMARY

The four textile processes of stitching, weaving, braiding and knitting, have the

potential to significantly reduce the cost of manufacturing many composite components

and prodhce structures that have improved mechanical performance in critical design

cases such as impact. Each of these processes has been briefly described here and their

advantages and limitations noted. The main aspects of these manufacturing techniques

have been summarised in Table 2.1 and reviews of these textile processes can be found

in the published literature (KO, 1989b; Mouritz et al., 1999; Kamiya et al., 2000).

However, one manufacturing issue that has only been only briefly mentioned here is the

potential of each manufacturing process to cause significant damage to the

reinforcement yarns and thus degrade the performance of the final composite. Although

this issue as been partly explored for the stitching process (Mouritz et al., 1997; Mouritz

and Cox, 2000) very little investigation has been done on the other techniques

mentioned here, although recent work has shown that the effects of processing damage

can be significant for 3D weaving (Lee et al., in press).