Page 61 - 3D Fibre Reinforced Polymer Composites

P. 61

50 30 Fibre Reinforced Polymer Composites

preform to the required fibre volume fraction and also add to the pressure that is forcing

the resin to flow.

An advantage of the RFI technique is that, in a similar fashion to prepreg

manufacture, only one major tool is needed in the process. For complex parts caul plates

and small tools to aid in the compaction of specific areas are often used, however the

tooling costs associated with RFI are generally much lower than with RTM.

To vacuum

I

release film

Heat & Pressure

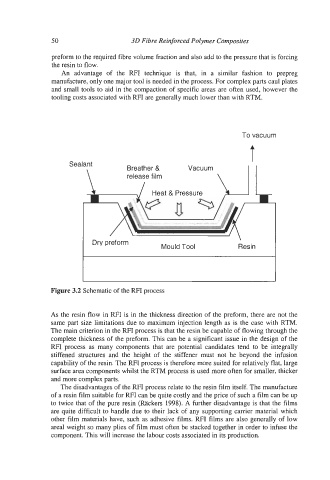

Figure 3.2 Schematic of the RFI process

As the resin flow in RFI is in the thickness direction of the preform, there are not the

same part size limitations due to maximum injection length as is the case with RTM.

The main criterion in the RFI process is that the resin be capable of flowing through the

complete thickness of the preform. This can be a significant issue in the design of the

RFI process as many components that are potential candidates tend to be integrally

stiffened structures and the height of the stiffener must not be beyond the infusion

capability of the resin. The RFI process is therefore more suited for relatively flat, large

surface area components whilst the RTM process is used more often for smaller, thicker

and more complex parts.

The disadvantages of the RFI process relate to the resin film itself. The manufacture

of a resin film suitable for RFI can be quite costly and the price of such a film can be up

to twice that of the pure resin (Rackers 1998). A further disadvantage is that the films

are quite difficult to handle due to their lack of any supporting carrier material which

other film materials have, such as adhesive films. RFI films are also generally of low

areal weight so many plies of film must often be stacked together in order to infuse the

component. This will increase the labour costs associated in its production.