Page 62 - 3D Fibre Reinforced Polymer Composites

P. 62

Preform Consolidation 51

There do not appear to be any other processing techniques, related to RFI, that are

known under different names. The main variation within the RFI process appears to be

whether the infusion is conducted in an oven under vacuum pressure or in an autoclave

with an additional autoclave-generated pressure.

3.2.3 SCRIMP-based Techniques

The Seemann Composite Resin Infusion Process (SCRIMP) and similar techniques are

essentially a mixture of the RTM and FWI processes. Like the RTM process, SCRIMP

introduces liquid resin from an external source into the part via a resin inlet port.

However, in a similar fashion to RFI, the primary resin flow direction is through the

thickness of the preform. This style of resin flow is accomplished through the use of a

resin distribution medium which allows the resin to flow quickly over the surface area

of the part as it is also infusing through the preform thickness.

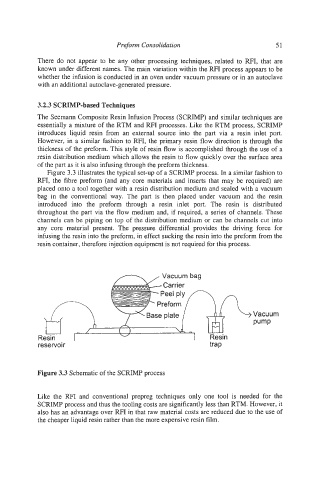

Figure 3.3 illustrates the typical set-up of a SCRIMP process. In a similar fashion to

RFI, the fibre preform (and any core materials and inserts that may be required) are

placed onto a tool together with a resin distribution medium and sealed with a vacuum

bag in the conventional way. The part is then placed under vacuum and the resin

introduced into the preform through a resin inlet port. The resin is distributed

throughout the part via the flow medium and, if required, a series of channels. These

channels can be piping on top of the distribution medium or can be channels cut into

any core material present. The pressure differential provides the driving force for

infusing the resin into the preform, in effect sucking the resin into the preform from the

resin container, therefore injection equipment is not required for this process.

Vacuum

Pump

R

reservoir trap

Figure 3.3 Schematic of the SCRIMP process

Like the RFI and conventional prepreg techniques only one tool is needed for the

SCRIMP process and thus the tooling costs are significantly less than RTM. However, it

also has an advantage over RFI in that raw material costs are reduced due to the use of

the cheaper liquid resin rather than the more expensive resin film.