Page 65 - 3D Fibre Reinforced Polymer Composites

P. 65

54 30 Fibre Reinforced Polymer Composites

container, which can limit the volume of resin that can be handled. A heated pressure

pot is an example of a constant pressure system.

Constant flow rate systems are usually driven by reciprocating piston pumps and

enable repeatable injection times to be maintained, which is important for production-

line manufacturing. With these pumps flow is actually semi-constant as flow of a set

volume of resin occurs during the piston downstroke and it is stopped during the piston

upstroke when resin is drawn in. The advantages of this system include flow rate

control, larger resin reservoirs and the ability to have higher injection pressures. The

main disadvantage comes from the increasing backpressure generated as the resin flows

through the preform. If this pressure becomes too high then the preform can be

displaced within the mould and can even cause mould deflection and damage to the

equipment. If the flow front is also moving too rapidly in the preform then void

entrapment can result, leading to a poor quality part.

Fortunately, many suppliers of injection equipment can now supply systems capable

of control over both the flow rate and pressure and contact details for some of these

companies are given in Table 3.1.

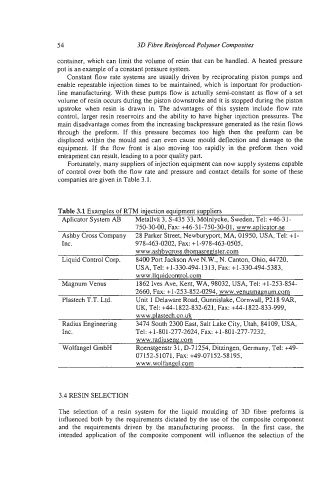

Tabie 3.1 Examples of RTM injection equipment suppliers

Aplicator System AB Metallva 3, S-435 33, Mdlnlycke, Sweden, Tel: +46-31-

750-30-00, Fax: +46-3 1-750-30-01, www.avlicator.se

Ashby Cross Company 28 Parker Street, Newburyport, MA, 01950, USA, Tel: +1-

Inc . 978-463-0202, Fax: + 1-978-463-0505,

www.ashbvcross.thomasreoister.com

Liquid Control Corp. 8400 Port Jackson Ave N.W., N. Canton, Ohio, 44720,

USA, Tel: +1-330-494-1313, Fax: + 1-330-494-5383,

www.liauidcontrol.com

Magnum Venus 1862 Ives Ave, Kent, WA, 98032, USA, Tel: +1-253-854-

2660, Fax: + 1-253-852-0294, www.venusmagnum.com

Plastech T.T. Ltd. Unit 1 Delaware Road, Gunnislake, Cornwall, P218 9AR,

UK, Tel: +44-1822-832-621, Fax: +44-1822-833-999,

www.vlastech.co.uk

Radius Engineering 3474 South 2300 East, Salt Lake City, Utah, 84109, USA,

Inc. Tel: +1-801-277-2624, Fax: +1-801-277-7232,

www.radiusena.com

Wolfangel GmbH Roenstgenstr 3 1, D-7 1254, Ditzingen, Germany, Tel: +49-

07152-51071, Fax: +49-07152-58195,

www. wolfangel .com

3.4 RESIN SELECTION

The selection of a resin system for the liquid moulding of 3D fibre preforms is

influenced both by the requirements dictated by the use of the composite component

and the requirements driven by the manufacturing process. In the first case, the

intended application of the composite component will influence the selection of the