Page 80 - Hybrid Enhanced Oil Recovery Using Smart Waterflooding

P. 80

72 Hybrid Enhanced Oil Recovery using Smart Waterflooding 0.5

Differential Pressure (mbar) 4000 Reversing the core 0.4 Injection Rate (ml/min)

5000

4500

3500

0.3

3000

injection face

2500

2000

0.2

1500

1000

500

0

0 0.1

0 3 6 9 12 15

Pore Volumes Injected (PVinj)

R4: Berea - 300 ppm high salinity polymer solution

R3: Berea - 300 ppm high salinity LPS solution

R4: Injection Rate

R3: Injection Rate

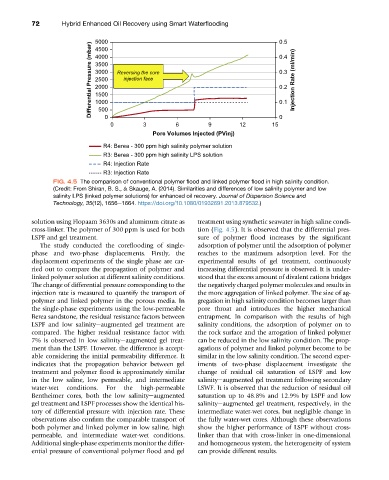

FIG. 4.5 The comparison of conventional polymer flood and linked polymer flood in high salinity condition.

(Credit: From Shiran, B. S., & Skauge, A. (2014). Similarities and differences of low salinity polymer and low

salinity LPS (linked polymer solutions) for enhanced oil recovery. Journal of Dispersion Science and

Technology, 35(12), 1656e1664. https://doi.org/10.1080/01932691.2013.879532.)

solution using Flopaam 3630s and aluminum citrate as treatment using synthetic seawater in high saline condi-

cross-linker. The polymer of 300 ppm is used for both tion (Fig. 4.5). It is observed that the differential pres-

LSPF and gel treatment. sure of polymer flood increases by the significant

The study conducted the coreflooding of single- adsorption of polymer until the adsorption of polymer

phase and two-phase displacements. Firstly, the reaches to the maximum adsorption level. For the

displacement experiments of the single phase are car- experimental results of gel treatment, continuously

ried out to compare the propagation of polymer and increasing differential pressure is observed. It is under-

linked polymer solution at different salinity conditions. stood that the excess amount of divalent cations bridges

The change of differential pressure corresponding to the the negatively charged polymer molecules and results in

injection rate is measured to quantify the transport of the more aggregation of linked polymer. The size of ag-

polymer and linked polymer in the porous media. In gregation in high salinity condition becomes larger than

the single-phase experiments using the low-permeable pore throat and introduces the higher mechanical

Berea sandstone, the residual resistance factors between entrapment. In comparison with the results of high

LSPF and low salinityeaugmented gel treatment are salinity conditions, the adsorption of polymer on to

compared. The higher residual resistance factor with the rock surface and the arrogation of linked polymer

7% is observed in low salinityeaugmented gel treat- can be reduced in the low salinity condition. The prop-

ment than the LSPF. However, the difference is accept- agations of polymer and linked polymer become to be

able considering the initial permeability difference. It similar in the low salinity condition. The second exper-

indicates that the propagation behavior between gel iments of two-phase displacement investigate the

treatment and polymer flood is approximately similar change of residual oil saturation of LSPF and low

in the low saline, low permeable, and intermediate salinityeaugmented gel treatment following secondary

water-wet conditions. For the high-permeable LSWF. It is observed that the reduction of residual oil

Bentheimer cores, both the low salinityeaugmented saturation up to 48.8% and 12.9% by LSPF and low

gel treatment and LSPF processes show the identical his- salinityeaugmented gel treatment, respectively, in the

tory of differential pressure with injection rate. These intermediate water-wet cores, but negligible change in

observations also confirm the comparable transport of the fully water-wet cores. Although these observations

both polymer and linked polymer in low saline, high show the higher performance of LSPF without cross-

permeable, and intermediate water-wet conditions. linker than that with cross-linker in one-dimensional

Additional single-phase experiments monitor the differ- and homogeneous system, the heterogeneity of system

ential pressure of conventional polymer flood and gel can provide different results.