Page 215 - A Practical Companion to Reservoir Stimulation

P. 215

PRACTICAL COMPANION TO RESERVOIR STIMULATION

problem if the fluids used in the treatment are of low viscosity most hydraulic fracturing schedules using diverters are sim-

and create an equilibrium proppant bank. With this type of ply broken up into even stages. The uneven in-situ parameters

proppant transport, the proppant bank will not be destroyed will cause slurry placement in the separate zones to create

during the overflush of the diverter. fractures of uneven geometries and conductivities.

Using conventional ball sealers to divert fracturing stages It is also very difficult to design and size the diverter stage

has many of the same inadequacies as bridging materials. It is so that all perforations in the zone being fractured become

extremely difficult to predict the seating efficiency of ball plugged and the other zones remain unaffected by the diverter.

sealers. This problem is even more difficult after proppant A diverter stage that is too large may plug the unfractured

has eroded the perforations. Also, the ball sealers must be intervals before the fracturing slurry designed for that stage

introduced into the fluid while proppant is being added. The has been pumped. If the diverter stage is too small, the first

presence of proppant will reduce the seating efficiencies, but zone my not be adequately plugged and the original fracture

it is impossible to predict by how much. If the ball sealers are may continue to accept fluid. Portions of the pad fluid in-

dropped in a clean fluid stage immediately following the tended for the second interval will overflush the proppant

proppant stages, the clean fluid will overflush proppant away pack away from the immediate wellbore. At the same time,

from the perforations until the balls finally seat. the second zone is losing critical volumes of pad fluid, which

Designing a schedule that assures precise proppant place- may result in an early screenout.

ment into multiple zones by using diverter stages is almost There is also no assurance that the rock properties vary

impossible. When several zones are open to the wellbore it is enough to prevent zones from accepting fluid simultaneously.

extremely difficult to calculate which zone will fracture first. Even if one zone initially accepts all the fluid, a second zone

The zones will almost surely be different in size and will have may begin to accept a portion of the treatment later in the

slightly different rock properties. Since it is not practically procedure. As net pressure in the fracture increases so does

possible to know which zone will fracture at a given time, the pressure in the wellbore. At some point the net pressure

Treating Treating Treating

Lowest Middle Upper

Zone Zone Zone

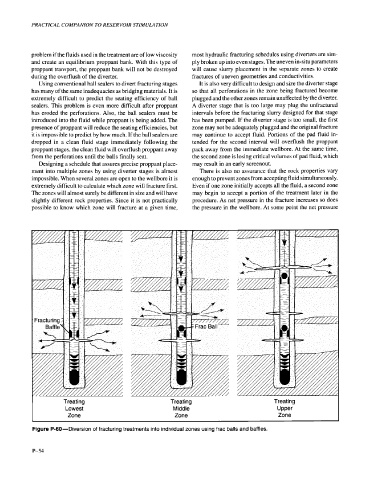

Figure P-60-Diversion of fracturing treatments into individual zones using frac balls and baffles.

P- 54