Page 37 - A Practical Introduction to Optical Mineralogy

P. 37

THE MICROSCOPIC STUDY OF MINERALS MICROHARDNESS (VHN)

challenges of the polishing technique has been to totally avoid relief Relative polishing hardness can be of value in the study of micro-

during polishing. This is because of the detrimental effect of polishing inclusions in an identified host phase; comparison of the hardness of an

relief on the appearance of the polished section, as well as the necessity inclusion and its surround may be used to estimate the hardness of the

for optically fiat polished surfaces for reflectance measurements. As inclusion or eliminate some of several possibilities resulting from

some polishing relief is advantageous in qualitative mineral identification attempted using optical properties. Similarly, if optical

identification it is often beneficial to enhance the polishing relief by properties cannot be used to identify a mineral with certainty, compari-

buffing the specimen for a few minutes using a mild abrasive such as son of polishing hardness with an identified coexisting mineral may help.

gamma alumina on a soft nap. For example, pyrrhotite is easily identified and may be associated with

Polishing relief results in a phenomenon known as the Kalb light line, pyrite or pentlandite, which are similar in appearance; however, pyrite is

which is similar in appearance to a Becke line. A sharp grain contact harder than pyrrhotite whereas pentlandite is softer.

between. a hard mineral such as pyrite and a soft mineral such as

chalcopyrite should appear as a thin dark line when the specimen is

exactly in focus. On defocusing slightly by increasing the <;listance be- 1.9 Microhardness (VHN)

tween the specimen and objective, a fine line of bright light should

appear along the grain contact in the softer mineral. The origin of this The determination of relative polishing hardness (Section 1.8) is used in

light line shourct easily be understood on examination of Figure 1.8. the mineral identification chart (Appendix C). Hardness can however

be measured quantita_tively using microindentation techniques. The

Ideally the light line should move away from the grain boundary as the

specimen is further defocused. On defocusing in the opposite sense the frequently used hardness value, the Vickers hardness number (VHN), is

given for each mineral listed in Appendix C.

light line appears in the harder mineral, and defocusing in this sense is

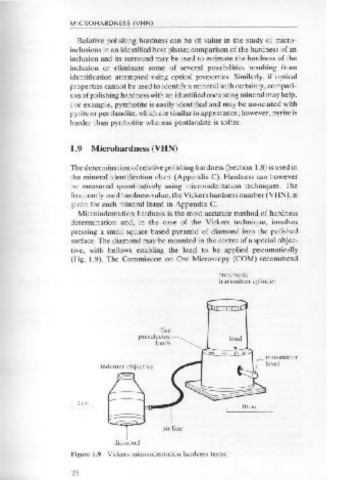

often necessary as the white line is difficult to see in a bright white soft Microindentation hardness is the most accurate method of hardness

determination and, in the case of the Vickers technique, involves

mineral. The light line is best seen using low power magnification and an

almost closed aperture diaphragm. pressing a small square based pyramid of diamond into the polished

urface. The diamond may be mounted in the centre of a special objec-

The Kalb light line is used to determine the relative polishing hardness

of minerals in contact in the same polished section. This sequence can be tive, with bellows enabling the load to be applied pneumatically

(Fig. 1.9). The Commission on Ore Microscopy (COM) recommend

used to confirm optical identification of the mineral set, or as an aid to

the identification of individual minerals, by comparison with published

pneumatic

lists of relative polishing hardness (e.g. Uytenbogaardt & Burke 1971 ). transmitter cylinder

five

preselected

loads

- ------ F2 transmitter

level

indenter objective

IO cm

Figure 1.8 Relative polishing hardness. The position of focus is first at F,. If the

specimen is now lowered away from the objective, the level that is in focus will I

diamond

move to F,, so that a light line (the ' Kalb light line') appears to move into the

softer substance. l•'l~:ure 1.9 Vickers microindentation hardness tester.

24 25