Page 40 - A Practical Introduction to Optical Mineralogy

P. 40

THE MICROSCOPIC STUDY OF MINERALS THIN- AND POLISHED-SECTION PREPARATION

crossed polars it should have four extinction positions at 90°, and the (3) Grinding the surface fiat using carborundum grit and water on a

polarisation colours seen in each quadrant should be identical. Adjust glass or a metal surface.

the polariser and analyser until the best results are obtained (see ( 4) Polishing the surface using diamond grit and an oily lubricant on a

Hallimond 1970, p. 101). relatively hard 'paper' lap.

Ensure that the stage is well centred using the high power objective (5) Buffing the surface using gamma alumina powder and water as

before studying optical figures. lubricant on a relatively soft 'cloth' lap.

There are many variants of this procedure, and the details usually

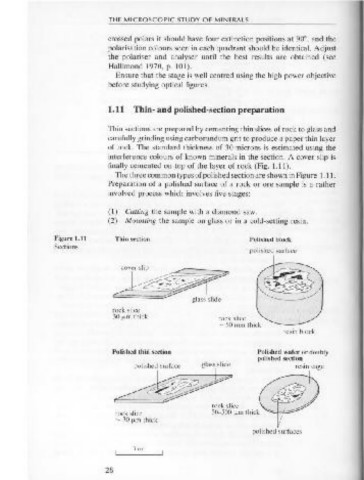

1.11 Thin- and polished-section preparation depend on the nature of the samples and the polishing materials, and

equipment that happen to be available. Whatever the method used, the

Thin sections are prepared by cementing thin slices of rock to glass and objective is a fiat, relief-free, scratch-free polished surface. The tech-

carefully grinding using carborundum grit to produce a paper thin layer nique used by the British Geological Survey is outlined by B. Lister

of rock. The standard thickness of 30 microns is estimated using the (1978).

interference colours of known minerals in the section. A cover slip is

finally cemented on top of the layer of rock (Fig. 1.11).

The three common types of polished section are shown in Figure 1.11.

Preparation of a polished surface of a rock or ore sample is a rather

involved process which involves five stages:

(1) Cutting the sample with a diamond saw.

(2) Mounting the sample on glass or in a cold-setting resin.

Figure 1.11 Thin section Polished block

Sections.

polished surface

~~

glass sltdc

rock slice

30 IJ.m thick rock slice

-50 mm thick

resin block

Polished thiri section Polished wafer or doubly

polished section

polished surface glass slide resin cage

~

rock slice

rock slice 50--500 IJ.m thick

- 30 IJ.m thick

polished surfaces

3cm

28 29