Page 107 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 107

Fracture Modes and Welding Defects

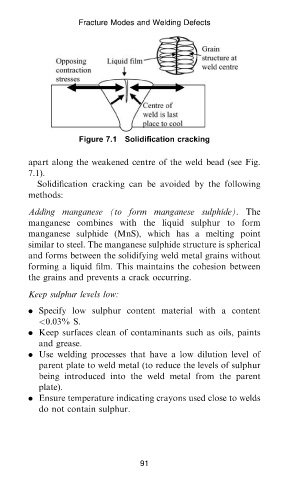

Figure 7.1 Solidification cracking

apart along the weakened centre of the weld bead (see Fig.

7.1).

Solidification cracking can be avoided by the following

methods:

Adding manganese (to form manganese sulphide). The

manganese combines with the liquid sulphur to form

manganese sulphide (MnS), which has a melting point

similar to steel. The manganese sulphide structure is spherical

and forms between the solidifying weld metal grains without

forming a liquid film. This maintains the cohesion between

the grains and prevents a crack occurring.

Keep sulphur levels low:

. Specify low sulphur content material with a content

<0.03% S.

. Keep surfaces clean of contaminants such as oils, paints

and grease.

. Use welding processes that have a low dilution level of

parent plate to weld metal (to reduce the levels of sulphur

being introduced into the weld metal from the parent

plate).

. Ensure temperature indicating crayons used close to welds

do not contain sulphur.

91

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200907QG Welding chap7.3d Page 91 of 107