Page 111 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 111

Fracture Modes and Welding Defects

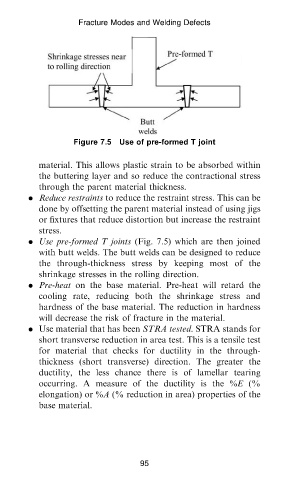

Figure 7.5 Use of pre-formed T joint

material. This allows plastic strain to be absorbed within

the buttering layer and so reduce the contractional stress

through the parent material thickness.

. Reduce restraints to reduce the restraint stress. This can be

done by offsetting the parent material instead of using jigs

or fixtures that reduce distortion but increase the restraint

stress.

. Use pre-formed T joints (Fig. 7.5) which are then joined

with butt welds. The butt welds can be designed to reduce

the through-thickness stress by keeping most of the

shrinkage stresses in the rolling direction.

. Pre-heat on the base material. Pre-heat will retard the

cooling rate, reducing both the shrinkage stress and

hardness of the base material. The reduction in hardness

will decrease the risk of fracture in the material.

. Use material that has been STRA tested. STRA stands for

short transverse reduction in area test. This is a tensile test

for material that checks for ductility in the through-

thickness (short transverse) direction. The greater the

ductility, the less chance there is of lamellar tearing

occurring. A measure of the ductility is the %E (%

elongation) or %A (% reduction in area) properties of the

base material.

95

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200907QG Welding chap7.3d Page 95 of 107