Page 110 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 110

A Quick Guide to Welding and Weld Inspection

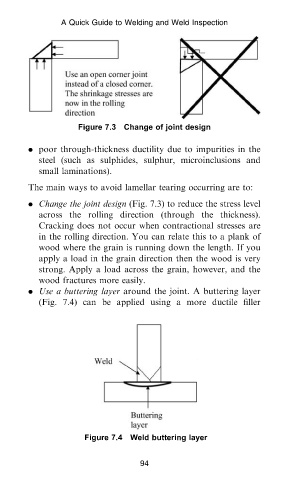

Figure 7.3 Change of joint design

. poor through-thickness ductility due to impurities in the

steel (such as sulphides, sulphur, microinclusions and

small laminations).

The main ways to avoid lamellar tearing occurring are to:

. Change the joint design (Fig. 7.3) to reduce the stress level

across the rolling direction (through the thickness).

Cracking does not occur when contractional stresses are

in the rolling direction. You can relate this to a plank of

wood where the grain is running down the length. If you

apply a load in the grain direction then the wood is very

strong. Apply a load across the grain, however, and the

wood fractures more easily.

. Use a buttering layer around the joint. A buttering layer

(Fig. 7.4) can be applied using a more ductile filler

Figure 7.4 Weld buttering layer

94

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200907QG Welding chap7.3d Page 94 of 107