Page 109 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 109

Fracture Modes and Welding Defects

Reheat cracking

Reheat cracking occurs primarily in the HAZ of thick-section

high strength low alloy (HSLA) steels, 300 series stainless

steels and nickel-based alloys. During PWHT or elevated

service temperatures intergranular cracking can occur due to

stress relaxation in coarse grained regions under high

restraint or residual stresses. The failure normally initiates

at a stress concentration such as a notch or change in cross-

section. Reheat cracking can be avoided by:

. adequate preheating to reduce the stress levels in the HAZ;

. using joint designs that require less restraint during

welding in thick sections;

. removing stress concentrations caused by sharp changes in

cross-section, such as sharp undercut, mechanical damage

and poorly blended weld toes.

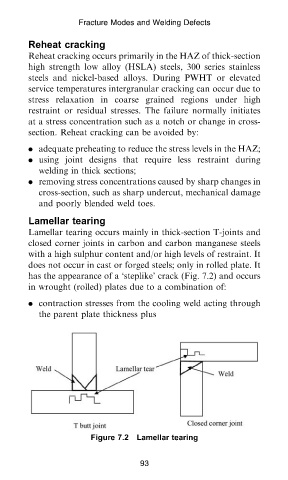

Lamellar tearing

Lamellar tearing occurs mainly in thick-section T-joints and

closed corner joints in carbon and carbon manganese steels

with a high sulphur content and/or high levels of restraint. It

does not occur in cast or forged steels; only in rolled plate. It

has the appearance of a ‘steplike’ crack (Fig. 7.2) and occurs

in wrought (rolled) plates due to a combination of:

. contraction stresses from the cooling weld acting through

the parent plate thickness plus

Figure 7.2 Lamellar tearing

93

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200907QG Welding chap7.3d Page 93 of 107