Page 113 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 113

Fracture Modes and Welding Defects

Weld decay

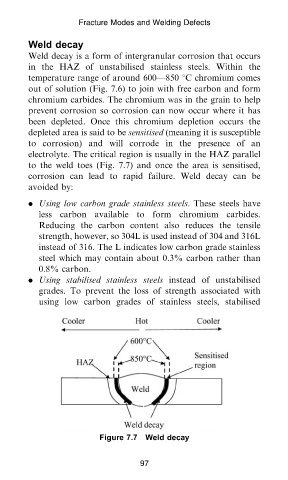

Weld decay is a form of intergranular corrosion that occurs

in the HAZ of unstabilised stainless steels. Within the

temperature range of around 600—850 8C chromium comes

out of solution (Fig. 7.6) to join with free carbon and form

chromium carbides. The chromium was in the grain to help

prevent corrosion so corrosion can now occur where it has

been depleted. Once this chromium depletion occurs the

depleted area is said to be sensitised (meaning it is susceptible

to corrosion) and will corrode in the presence of an

electrolyte. The critical region is usually in the HAZ parallel

to the weld toes (Fig. 7.7) and once the area is sensitised,

corrosion can lead to rapid failure. Weld decay can be

avoided by:

. Using low carbon grade stainless steels. These steels have

less carbon available to form chromium carbides.

Reducing the carbon content also reduces the tensile

strength, however, so 304L is used instead of 304 and 316L

instead of 316. The L indicates low carbon grade stainless

steel which may contain about 0.3% carbon rather than

0.8% carbon.

. Using stabilised stainless steels instead of unstabilised

grades. To prevent the loss of strength associated with

using low carbon grades of stainless steels, stabilised

Figure 7.7 Weld decay

97

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200907QG Welding chap7.3d Page 97 of 107