Page 117 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 117

Fracture Modes and Welding Defects

consumables. Moisture, grease, paint or oil on the

material surface or filler wire are common sources of

hydrogen leading to porosity.

Solid inclusions

Solid inclusions (Fig. 7.9) can be metallic (i.e. tungsten,

copper, etc.) or non-metallic (i.e. slag) and are formed within

the weld metal. Causes of solid inclusions include:

. inadequate cleaning of slag originating from the welding

flux;

. inadequate removal of silica inclusions in ferritic steels

during MAG or TIG welding;

. touching the tungsten to the weld pool during TIG

welding;

. the melting of the copper contact tube into the weld pool

during MIG/MAG welding.

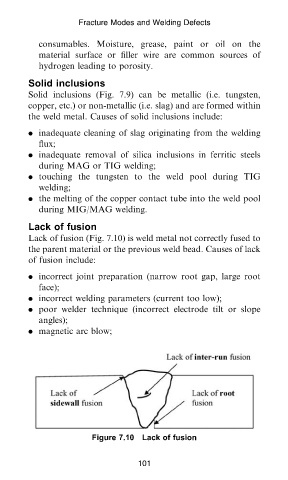

Lack of fusion

Lack of fusion (Fig. 7.10) is weld metal not correctly fused to

the parent material or the previous weld bead. Causes of lack

of fusion include:

. incorrect joint preparation (narrow root gap, large root

face);

. incorrect welding parameters (current too low);

. poor welder technique (incorrect electrode tilt or slope

angles);

. magnetic arc blow;

Figure 7.10 Lack of fusion

101

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200907QG Welding chap7.3d Page 101 of 107