Page 121 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 121

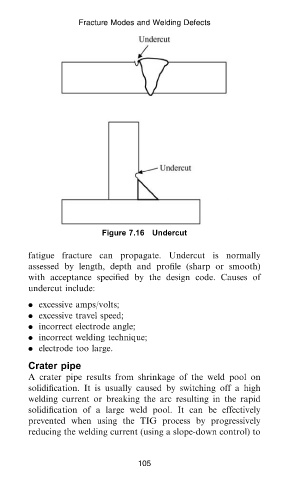

Fracture Modes and Welding Defects

Figure 7.16 Undercut

fatigue fracture can propagate. Undercut is normally

assessed by length, depth and profile (sharp or smooth)

with acceptance specified by the design code. Causes of

undercut include:

. excessive amps/volts;

. excessive travel speed;

. incorrect electrode angle;

. incorrect welding technique;

. electrode too large.

Crater pipe

A crater pipe results from shrinkage of the weld pool on

solidification. It is usually caused by switching off a high

welding current or breaking the arc resulting in the rapid

solidification of a large weld pool. It can be effectively

prevented when using the TIG process by progressively

reducing the welding current (using a slope-down control) to

105

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200907QG Welding chap7.3d Page 105 of 107