Page 119 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 119

Fracture Modes and Welding Defects

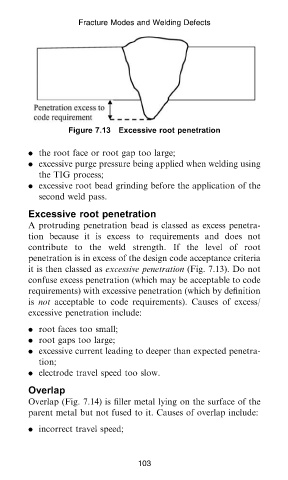

Figure 7.13 Excessive root penetration

. the root face or root gap too large;

. excessive purge pressure being applied when welding using

the TIG process;

. excessive root bead grinding before the application of the

second weld pass.

Excessive root penetration

A protruding penetration bead is classed as excess penetra-

tion because it is excess to requirements and does not

contribute to the weld strength. If the level of root

penetration is in excess of the design code acceptance criteria

it is then classed as excessive penetration (Fig. 7.13). Do not

confuse excess penetration (which may be acceptable to code

requirements) with excessive penetration (which by definition

is not acceptable to code requirements). Causes of excess/

excessive penetration include:

. root faces too small;

. root gaps too large;

. excessive current leading to deeper than expected penetra-

tion;

. electrode travel speed too slow.

Overlap

Overlap (Fig. 7.14) is filler metal lying on the surface of the

parent metal but not fused to it. Causes of overlap include:

. incorrect travel speed;

103

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200907QG Welding chap7.3d Page 103 of 107