Page 120 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 120

A Quick Guide to Welding and Weld Inspection

Figure 7.14 Overlap

. incorrect welding technique;

. current too low.

Underfill

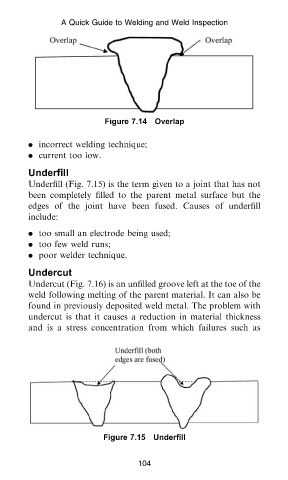

Underfill (Fig. 7.15) is the term given to a joint that has not

been completely filled to the parent metal surface but the

edges of the joint have been fused. Causes of underfill

include:

. too small an electrode being used;

. too few weld runs;

. poor welder technique.

Undercut

Undercut (Fig. 7.16) is an unfilled groove left at the toe of the

weld following melting of the parent material. It can also be

found in previously deposited weld metal. The problem with

undercut is that it causes a reduction in material thickness

and is a stress concentration from which failures such as

Figure 7.15 Underfill

104

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200907QG Welding chap7.3d Page 104 of 107