Page 351 - Accounting Information Systems

P. 351

322 PART II Transaction Cycles and Business Processes

Lean requires a constant state of quality control along with the authority to take immediate action. When

Toyota first introduced TPS, its production employees had the authority to shut down the line when

defects were discovered. In the early days, the line was often shut down to bring attention to a problem.

Whether caused by a defective part from a vendor or a faulty machine in a cell, the problem was properly

addressed so that it did not recur. After an adjustment period, the process stabilized.

Techniques and Technologies That Promote

Lean Manufacturing

Modern consumers want quality products, they want them quickly, and they want variety of choice.

This demand profile imposes a fundamental conflict for traditional manufacturers, whose structured

and inflexible orientation renders them ineffective in this environment. In contrast, lean companies

meet the challenges of modern consumerism by achieving manufacturing flexibility. This section

examines techniques and technologies that lean manufacturing firms employ to achieve manufacturing

flexibility.

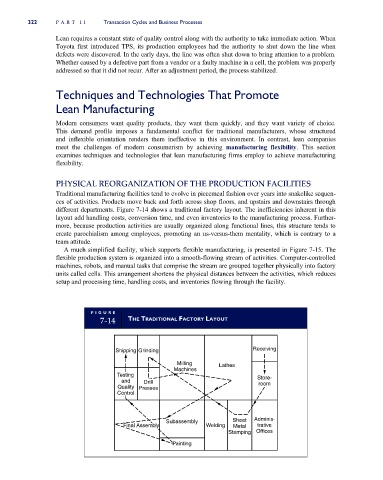

PHYSICAL REORGANIZATION OF THE PRODUCTION FACILITIES

Traditional manufacturing facilities tend to evolve in piecemeal fashion over years into snakelike sequen-

ces of activities. Products move back and forth across shop floors, and upstairs and downstairs through

different departments. Figure 7-14 shows a traditional factory layout. The inefficiencies inherent in this

layout add handling costs, conversion time, and even inventories to the manufacturing process. Further-

more, because production activities are usually organized along functional lines, this structure tends to

create parochialism among employees, promoting an us-versus-them mentality, which is contrary to a

team attitude.

A much simplified facility, which supports flexible manufacturing, is presented in Figure 7-15. The

flexible production system is organized into a smooth-flowing stream of activities. Computer-controlled

machines, robots, and manual tasks that comprise the stream are grouped together physically into factory

units called cells. This arrangement shortens the physical distances between the activities, which reduces

setup and processing time, handling costs, and inventories flowing through the facility.

FI GU RE

7-14 THE TRADITIONAL FACTORY LAYOUT

Shipping Grinding Receiving

Milling Lathes

Machines

Testing Store-

and Drill room

Quality Presses

Control

Subassembly Sheet Adminis-

Final Assembly Welding Metal trative

Stamping Offices

Painting