Page 352 - Accounting Information Systems

P. 352

C H A P TER 7 The Conversion Cycle 323

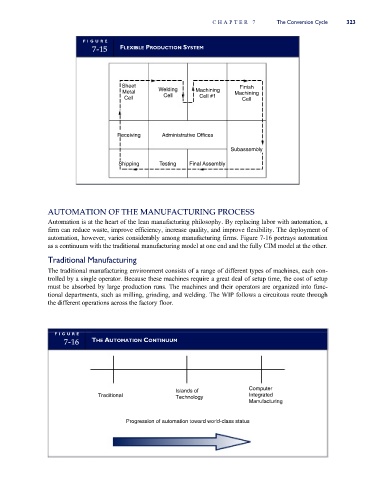

FI G U R E

7-15 FLEXIBLE PRODUCTION SYSTEM

Sheet Finish

Metal Welding Machining Machining

Cell Cell Cell #1 Cell

Receiving Administrative Offices

Subassembly

Shipping Testing Final Assembly

AUTOMATION OF THE MANUFACTURING PROCESS

Automation is at the heart of the lean manufacturing philosophy. By replacing labor with automation, a

firm can reduce waste, improve efficiency, increase quality, and improve flexibility. The deployment of

automation, however, varies considerably among manufacturing firms. Figure 7-16 portrays automation

as a continuum with the traditional manufacturing model at one end and the fully CIM model at the other.

Traditional Manufacturing

The traditional manufacturing environment consists of a range of different types of machines, each con-

trolled by a single operator. Because these machines require a great deal of setup time, the cost of setup

must be absorbed by large production runs. The machines and their operators are organized into func-

tional departments, such as milling, grinding, and welding. The WIP follows a circuitous route through

the different operations across the factory floor.

FI G U R E

7-16 THE AUTOMATION CONTINUUM

Computer

Islands of

Traditional Technology Integrated

Manufacturing

Progression of automation toward world-class status