Page 166 - Adsorbents fundamentals and applications

P. 166

ACTIVATED ALUMINA AS SPECIAL SORBENTS 151

100

4A Zeolite

Adsorbed, kg H 2 O/100kg 1 Activated alumina

10

Silica gel

0.1

0.01 0.1 1 10 100

Water vapor pressure, mm Hg

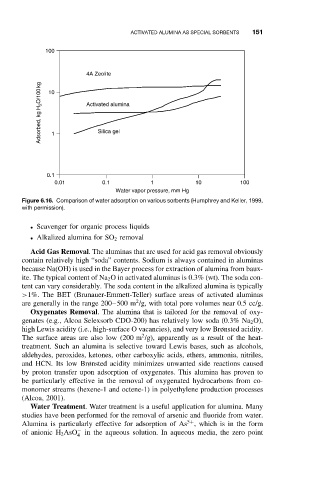

Figure 6.16. Comparison of water adsorption on various sorbents (Humphrey and Keller, 1999,

with permission).

• Scavenger for organic process liquids

• Alkalized alumina for SO 2 removal

Acid Gas Removal. The aluminas that are used for acid gas removal obviously

contain relatively high “soda” contents. Sodium is always contained in aluminas

because Na(OH) is used in the Bayer process for extraction of alumina from baux-

ite. The typical content of Na 2 O in activated aluminas is 0.3% (wt). The soda con-

tent can vary considerably. The soda content in the alkalized alumina is typically

>1%. The BET (Brunauer-Emmett-Teller) surface areas of activated aluminas

2

are generally in the range 200–500 m /g, with total pore volumes near 0.5 cc/g.

Oxygenates Removal. The alumina that is tailored for the removal of oxy-

genates (e.g., Alcoa Selexsorb CDO-200) has relatively low soda (0.3% Na 2 O),

high Lewis acidity (i.e., high-surface O vacancies), and very low Brønsted acidity.

2

The surface areas are also low (200 m /g), apparently as a result of the heat-

treatment. Such an alumina is selective toward Lewis bases, such as alcohols,

aldehydes, peroxides, ketones, other carboxylic acids, ethers, ammonia, nitriles,

and HCN. Its low Brønsted acidity minimizes unwanted side reactions caused

by proton transfer upon adsorption of oxygenates. This alumina has proven to

be particularly effective in the removal of oxygenated hydrocarbons from co-

monomer streams (hexene-1 and octene-1) in polyethylene production processes

(Alcoa, 2001).

Water Treatment. Water treatment is a useful application for alumina. Many

studies have been performed for the removal of arsenic and fluoride from water.

5+

Alumina is particularly effective for adsorption of As , which is in the form

of anionic H 2 AsO − in the aqueous solution. In aqueous media, the zero point

4